Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-09-25

Importance of selecting the right stone saw machine for countertops

Selecting the right stone saw machine is crucial for ensuring the precision and quality of cutting countertops made from materials like marble, granite, and quartz. A high-quality stone saw machine not only provides accurate cuts but also improves efficiency and reduces material waste. For countertops, machines like CNC bridge saws are ideal due to their ability to handle large stone slabs, offer various cutting options (straight, angled, or curved), and deliver smooth, polished edges. Choosing the right machine ensures durability, cost-effectiveness, and a professional finish in countertop production.

Overview of common countertop materials (granite, marble, quartz)

When it comes to crafting kitchen countertops, materials like granite, marble, and quartz are popular choices due to their durability, aesthetic appeal, and heat resistance. Granite is known for its strength and natural patterns, while marble offers a classic, elegant look with its veined texture. Quartz, an engineered stone, provides uniformity and requires less maintenance. Cutting these materials with precision is essential, and using the right stone saw machine ensures clean cuts, faster production, and minimized waste. Choosing the best machine depends on factors like material type, desired cuts, and production needs.

Overview of different machines used for stone cutting

When it comes to cutting countertops from marble, granite, or quartz, choosing the right stone saw machine is crucial for precision, efficiency, and versatility. Different machines offer unique advantages depending on the complexity of the project and material.

The 4+1 Stone Saw Machine excels in straight, angled, and curved cuts, making it highly adaptable.

1. The saw blades can tilt 0° or 360° for rotating

2. The bridge saw table is tilted at 85° to facilitate loading and unloading.

3. The main core components adopt international first-line brands which are more stable.

4. One-piece structure guarantees a small footprint and easy installation and movement.

5.The extra milling cutter, can easily realize stone digging holes or cutting countertop slabs with fast speed and high precision.

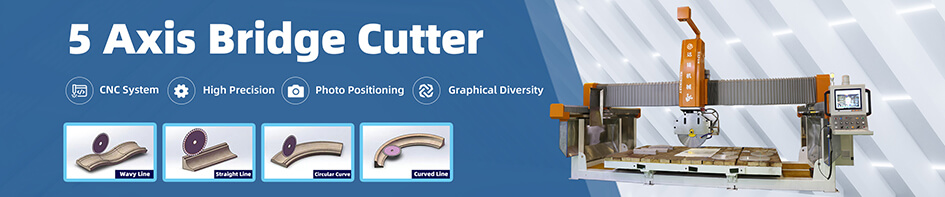

The 5-axis CNC bridge saw is a versatile machine capable of performing various complex stone cutting tasks, including:

Countertop cutting: Handles multiple types of cuts, such as slab cutting, chamfering, pothole creation, and custom angles.

Automatic cutting: Imports CAD designs for precise cuts without manual data input.

Bridge cutting: Offers standard bridge cutting features.

Roman column cutting: Cuts Roman column boards with simultaneous 45-degree chamfering.

Arc-shaped line cutting: Creates rough arc lines requiring manual polishing.

Concave-convex cutting: Shapes curved plates for decorative panels.

Abnormal shape cutting: Cuts irregular shapes for uneven walls.

5-Axis Waterjet Cutting Machine

User-Friendly Operation: Equipped with a CNC control system, it offers omnidirectional cutting capabilities, allowing for precise cuts on any plane curve with ease.

Superior Machining Accuracy: The machine’s reinforced bed structure ensures stability, preventing vibrations of the cutting head during high-speed operation. This design enables smooth machine performance, rapid cutting, and precise machining results.

Enhanced Production Efficiency: The cutting head has a reliable pneumatic high-pressure water switching control system, significantly boosting productivity and ensuring uninterrupted operation.

Efficient Water Backflow Prevention: Featuring an innovative sand valve design, the machine allows for smoother sand flow, is easier to maintain, and effectively prevents water backflow, increasing operational reliability.

Low Maintenance and Easy Cleaning: The stainless steel shield protects against dust, water, rust, and corrosion, making the machine durable and simple to clean, thus enhancing longevity and reducing downtime.

Granite Profile Cutting Machine

This Granite Profile Cutting Machine adopts a CNC control system and man-machine interactive operation interface, the body, and beam are seamlessly welded from thickened high-strength steel and processed by a CNC machining center with high precision, which is solid and stable and not easy to be deformed, and it is suitable for profiling and cutting profiled marble and granite, such as lines, Roman columns, large circular arc boards and so on.

Easy Handling: The speed control is a humanized one-button operation and is compatible with domestic and international CAM software such as Artcam Precision Engraving.

Remote Operation Support remote drawing import and online drawing function.

Power Failure ProtectionIndustrial grade control system, supports power failure memory, power failure recovery, and renewed engraving at broken points.

High Cutting Accuracy Adopting new heat-resistant and environment-resistant servo motors and drivers, the operation speed is extremely fast, the precision is extremely high, and the vibration resistance is extremely strong.

High Stability: The electric spindle adopts high bearing technology, high speed, low noise, high power, fast response, power performance, and stability is enough to

meet the needs of a high-speed machining rack; transmission parts using Taiwan screw, slider, square rail, etc., fine and smooth, to ensure that the machine runs at high speed and high precision.

Low Energy Consumption: Professional high-performance vector control inverter with excellent performance and intelligent power-saving function, smooth branching, and low power consumption

When selecting the ideal stone saw machine for cutting countertops, several key factors should guide your decision.

Material Compatibility: Different machines are better suited for specific materials such as granite, marble, or quartz. For example, CNC bridge saws are highly versatile, offering excellent performance across these materials, while water jet cutters may excel with intricate cuts on quartz.

Cutting Precision: Precision is critical when crafting custom countertop designs. Machines like 5-axis CNC saws provide unparalleled accuracy, allowing for smooth and intricate edge designs essential for high-end countertops.

Production Efficiency: The speed at which a machine processes countertops is vital for meeting production demands. Automatic saws tend to deliver faster results compared to manual machines, making them ideal for high-volume operations.

Ease of Operation: Modern saws often feature automated controls that streamline the cutting process, reducing the need for manual operation. Machines with automatic options are easier to use and more consistent, while manual control provides flexibility for custom jobs.

Maintenance and Durability: Long-term reliability and ease of maintenance are crucial when choosing a machine. CNC machines, for instance, are built for durability but require regular maintenance, while simpler machines may need fewer repairs but offer less versatility over time.