Price:

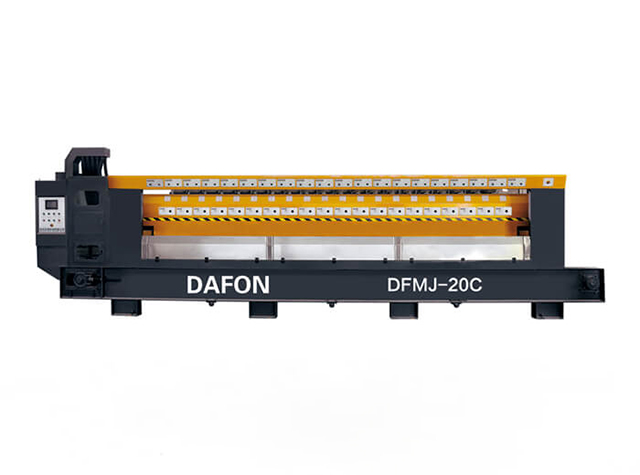

Brand Name: DAFON

Certification: CE, ISO

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Weight: Depends on head quantity

Application: stone/marble/granite

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

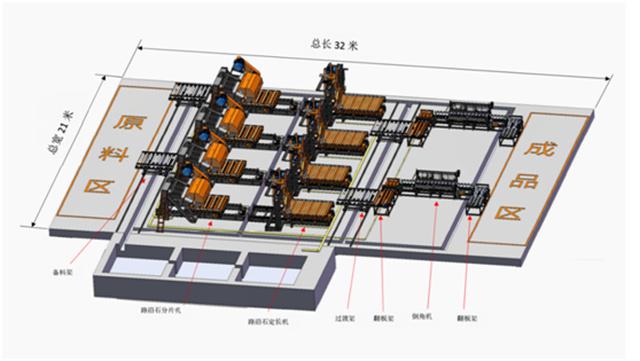

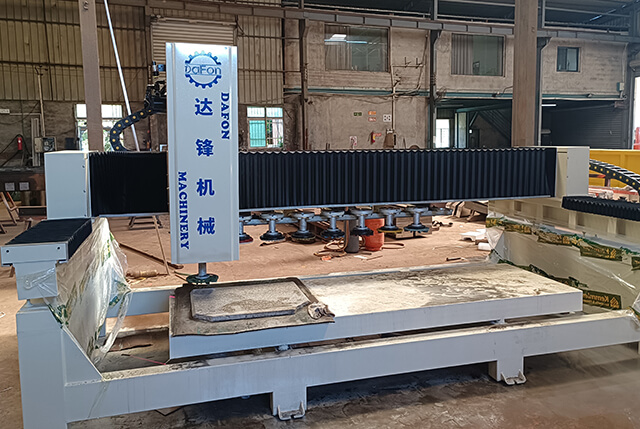

Fickert Head Marble Slab Polishing Machine is an automatic grinding and polishing production line used to process marble rough slabs and marble tiles from a two-way cutting machine. Fickert Head Marble Slab Polishing Machine consists of multiple grinding heads, including fixed thickness grinding head, grinding grinding head and polishing grinding head. Each grinding head uses a hydraulic device to exert working pressure on the processed plate, so the plate processed by the equipment has high processing accuracy and production efficiency.Generally, there is a special device at the input end of the production line to control the distance between two adjacent plates not to exceed the grinding range of the grinding head. Otherwise, the conveyor belt will stop on its own and all the grinding heads will automatically rise.

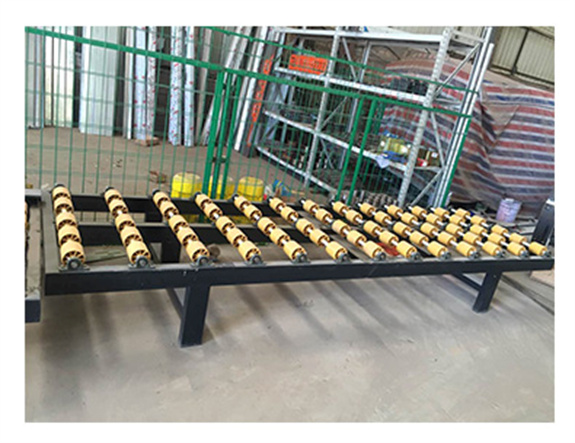

When the Fickert Head Marble Slab Polishing Machine is processing, the plate is sent to the workbench of the mill through a conveyor belt. The workbench is welded as a whole, the surface is machined, and the conveyor belt is installed. The workbench can be installed directly on the foundation foundation.

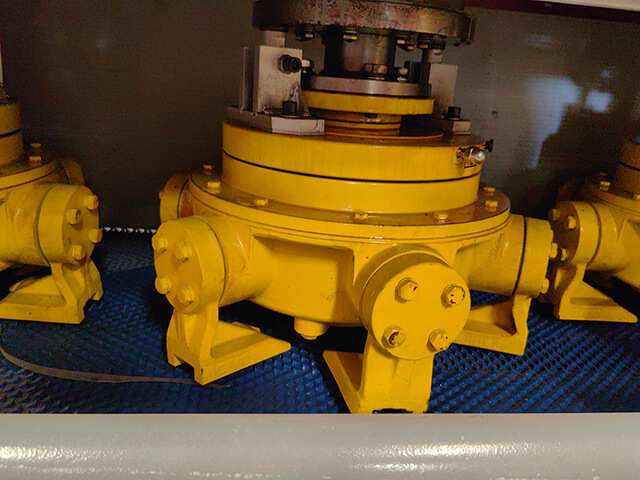

Conveyor belt rollers are installed at both ends of the machine, and a motor and a worm gear reducer are installed at the output end of the conveyor belt. The motor reducer drives the conveyor belt rollers to rotate, thereby driving the conveyor belt to move. Fickert Head Marble Slab Polishing Machine The conveyor belt conveying speed is adjusted through the frequency converter. In order to increase the friction between the conveyor belt and the stone, the surface of the conveyor belt is usually made into a convex and concave shape. The other side of the stone polishing machinery conveyor belt is equipped with a tension wheel to ensure that the conveyor belt always has a certain degree of stiffness and stability during processing.

Features

I. Suitable for the surface polishing granite/marble

II. Using PLC intelligent control system and through the LCD touch screen human-computer dialogue, to achieve intelligent control.

III. A grinding head automatic collision avoidance and shape memory function, and is configured to abrasive wear alarm device, the machine has high automation degree, low labor intensity.

IV. Allocation of special granite grinding head/marble elastic grinding, polishing and polishing quality, and greatly reduced abrasive consumption.

V. Selection of sophisticated, reasonable structure, improving processing technology. finishing strong rigidity. Stable performance.

VI. Grinding head, grinding head upper part and key bearings are used in the central automatic lubrication system.

VII. Grinding power transmission using joint belt teeth narrow V belt, greatly reducing the power loss and increase the service lift.

Techinical Data

|

Name |

Unit |

DF-16T |

|

Maximum grinding plate width |

mm |

2000 |

|

Crossbeam swing speed |

m/min |

3-35 |

|

Cross beam drive motor |

kw |

2x4 |

|

Belt drive speed |

m/min |

0.5-4 |

|

Belt drive power |

kw |

4 |

|

main motor power |

kw |

16x15 |

|

Number of grinding heads |

pcs |

16 |

|

Grinding disc diameter |

mm |

φ500 |

|

cooling water pressure |

Mpa |

0.1-0.15 |

|

compressed air |

Mpa |

≥0.7 |

|

Host size |

mm |

11500x3960x2600 |

|

Host total power |

kw |

252 |

FAQ:

Automatic Granite Polishing MachineTechnique Description : I.Suitable for the surface polishing granite/marble II.Using PLC intelligent control system and through the LCD touch s...

Stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodgi...

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu o...

Allocation the flexibility Resin polishing heads. Prominent improvement on the polishing efficiency and polishing quality and greatly reduced abrasive consumption. Marble stone po...

All purchased components and machine part are tested by our staff at QC department so that each and single part are of the exact quality and dimension as design...

Our experienced pre-sale team can provide full solution for stone factory and workshop planning, including Marble Slab Polishing Machine suggestion and necessar...

we can provide customers with technical support, training and after-sales service....

Improve production efficiency immediately and the automatic change heads function is very confinement2024-07-18

I've used this stone polisher machine for several months, and the results have been outstanding. It can automatic to change the polisher, so conveniently2024-07-15