Price:

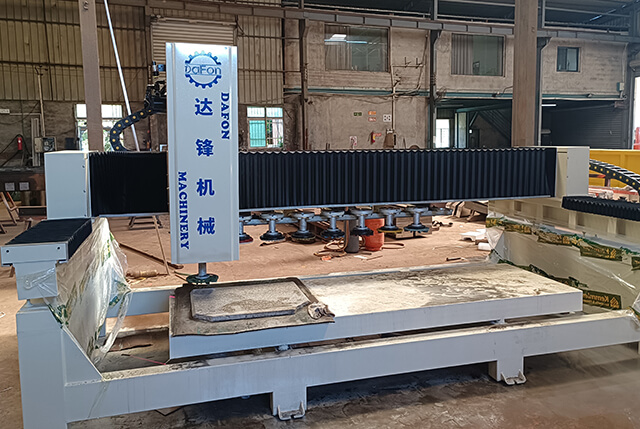

Brand Name: DAFON

Certification: CE, ISO

Model Number: DFB-LM3700

Power: 7kw

Weight: 4500kg

Application: thick stone/ kerbstone

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

This automatic single-head polishing machine is an automated device specially designed for large-sized stones such as thick plates and curbstones. It has many advanced functions such as automatic replacement of polishing grinding heads and independent grinding head control system, aiming to improve production efficiency, reduce labor costs, and meet the demand for high-quality stone processing.its is suitable for polishing large-sized stones such as thick slabs, curbstones, tombstones, etc.

| Name | Unit |

DFB-LM3700

|

|

Polishing pads

|

pcs

|

8

|

|

Max. processing size

|

mm

|

3700*2000*1500

|

|

Lifting stroke

|

mm

|

1000 |

|

Main motor

|

kw

|

7

|

|

Left and right X-axis planetary reducer

|

kw |

1.5

|

|

Front and rear Y-axis gear reducer

|

Kw | 1.5 |

|

Weight

|

kg

|

4500

|

|

Overall dimensions (L*W*H)

|

mm

|

6000*4500*2300

|

Performance Features

Automatic replacement of polishing grinding heads: The automatic head replacement system can be set through the PLC panel, and different types of polishing grinding heads can be automatically replaced according to the set polishing process to achieve continuous operation.

Independent grinding head control system: Each polishing grinding head is equipped with an independent control system, which can accurately set the polishing times, grinding head speed, pressure and other parameters to ensure the polishing quality of different workpieces.

Small site restrictions: Compared with the polishing machine line, this machine can be customized, occupies a small area, and is suitable for small processing plants

Cost-effective: Compared with the traditional manual polishing method, this equipment can greatly reduce labor costs, improve production efficiency, and has good economic benefits.

Easy to operate: The machine has a friendly operation interface and simple settings. It does not require high experience and skills from the operator and can be used after simple training.

Convenient abrasive replacement: The replacement of the polishing grinding head and the filling of the abrasive are very convenient, which greatly shortens the auxiliary time.

FAQ:

Introduction Technical Data Name Unit DFB-LM3700 Polishing pads pcs 8 Max. processing size mm 3700*2000*1500 Lifting stroke mm 1000 ...

Stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodgi...

Automatic Granite Polishing MachineTechnique Description : I.Suitable for the surface polishing granite/marble II.Using PLC intelligent control system and through the LCD touch s...

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu o...

We have extensive Gantry Type Single Head Polishing Machine installation experience both at home and abroad and can provide our customers with suitable installa...

we can production kerbstone cutting machine,infrared stone cutting machine, bridge saw machine, stone polishing machine, stone grinding machine,stone chamfering...

(1)Warranty: One year warranty for machines, 6 month for scharger and other accessories. (2)Please send back the defective goods which are within the warranty p...

Improve production efficiency immediately and the automatic change heads function is very confinement2024-07-18

I've used this stone polisher machine for several months, and the results have been outstanding. It can automatic to change the polisher, so conveniently2024-07-15