Price:

Brand Name: DAFON

Certification: CE, ISO

Model Number: DFL-SM6+6/8+8

Power: 7.5KW

Weight: Depends on head quantity

Application: Art & Craft, Stone Industry

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

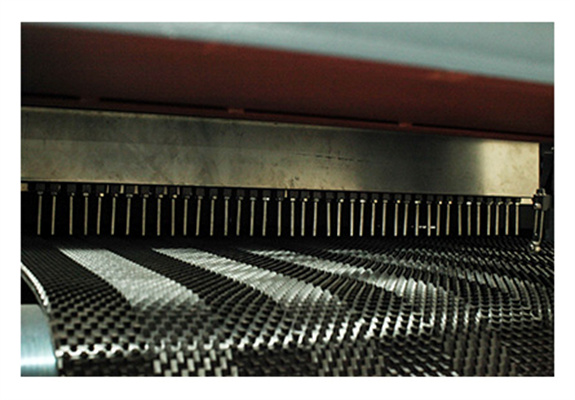

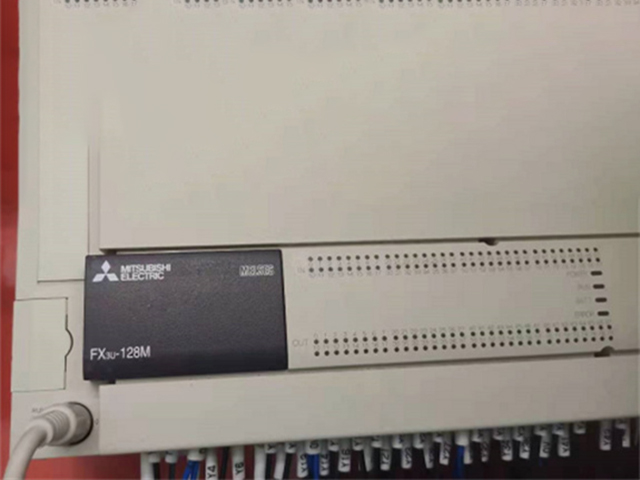

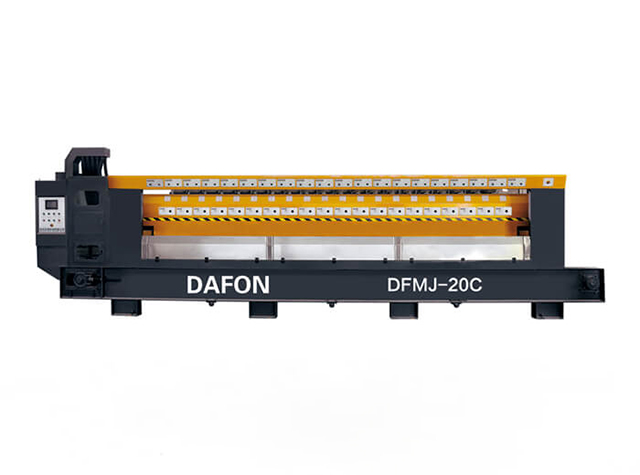

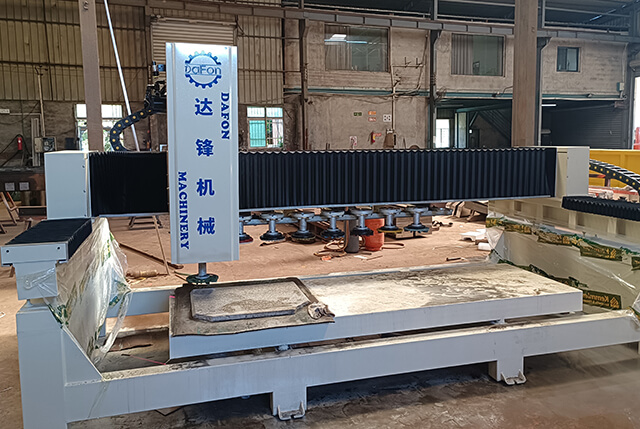

The polisher machine is designed to meet the market's high-quality demand for kerb stones. It uses a high-speed rotating grinding disc to remove unevenness on the surface of the kerb stones through grinding and polishing, making the surface smooth, flat, and beautiful. At the same time, it is equipped with a PLC programmable control system and a human-computer interactive operation interface, which is simple to operate, and has high production efficiency and stable performance. Suitable for surface polishing of kerb stones, capstones, tombstones, and other products.

Performance Features

High production efficiency: Using the method of simultaneous processing and polishing of planes and sides to replace the traditional manual polishing process, 30% to 50% of labor costs can be saved and production efficiency can be significantly improved.

Excellent external scalability: This equipment can be connected to the kerb stone processing line to reduce manual loading and unloading time, thus improving production efficiency.

Excellent stability: The equipment motor, bearings, pressure rollers, hydraulic accessories, etc. are all from domestic and foreign first-tier brands to ensure more stable operation of the equipment.

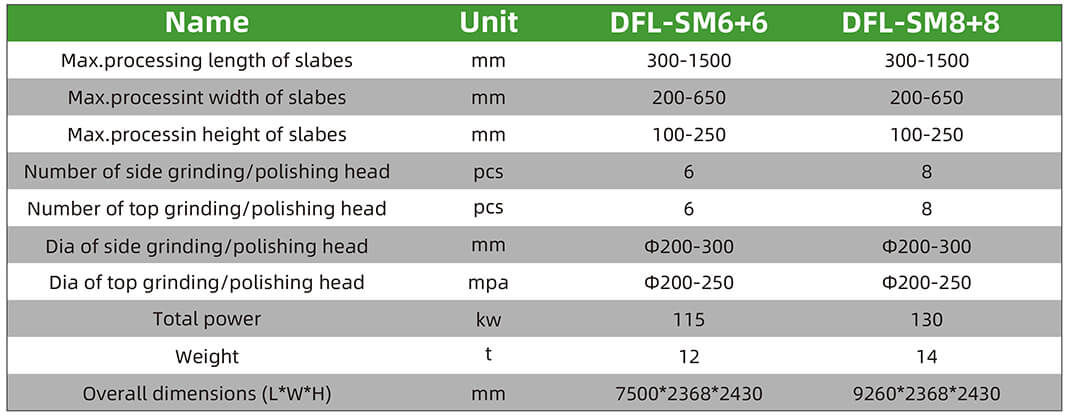

Technical Parameters

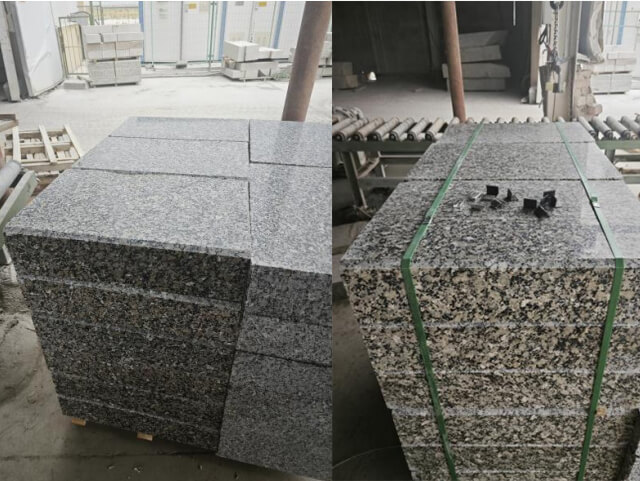

Finish Products

FAQ:

Stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodgi...

Allocation the flexibility Resin polishing heads. Prominent improvement on the polishing efficiency and polishing quality and greatly reduced abrasive consumption. Marble stone po...

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu o...

Introduction Technical Data Name Unit DFB-LM3700 Polishing pads pcs 8 Max. processing size mm 3700*2000*1500 Lifting stroke mm 1000 ...

we can provide customers with technical support, training and after-sales service....

We offer a six-month warranty on Line polishing machine for Kerbstone....

We are able to provide stone machine solutions to our customers in a timely and efficient manner....

I've used this stone polisher machine for several months, and the results have been outstanding. It can automatic to change the polisher, so conveniently2024-07-15

Improve production efficiency immediately and the automatic change heads function is very confinement2024-07-18