Price:

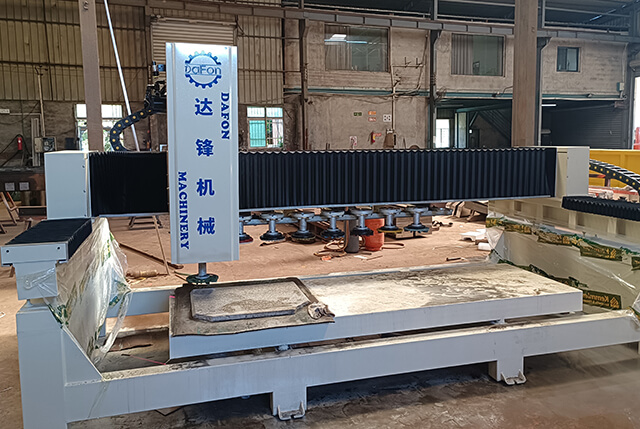

Brand Name: DAFON

Certification: CE, ISO

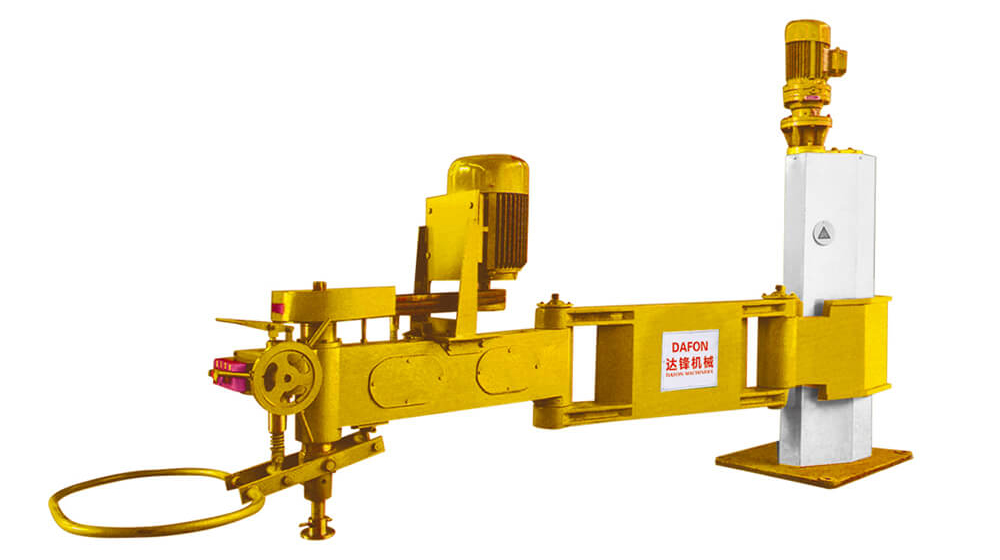

Model Number: DFB-SF2500/3000

Power: 6.1kw

Weight: 850-900kg

Application: stone/marble/granite

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

|

Name |

Unit |

DFB-SF2500 |

DFB-SF3000 |

|

Spindle lifting range |

mm |

80 |

80 |

|

Max.lifting stroke |

mm |

470 |

470 |

|

Main motor power |

kw |

5.5 |

5.5 |

|

Total power |

kw | 6.1 | 6.1 |

|

Weight |

kg |

850 | 900 |

|

Overall dimensions(L*W*H) |

mm |

3200*1650*1800 |

3800*1650*1800 |

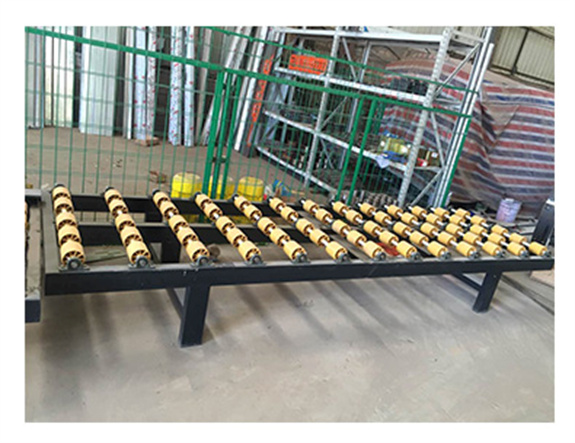

Lower cost: Lower cost, suitable for scenarios with limited budget or small-scale production.

Flexibility: Operators can manually adjust and control according to specific conditions, resulting in higher flexibility.

Wide range of applications: Since there is no need to rely on complex automation systems, the manual stone polishing machine is more versatile and suitable for stone of various sizes, shapes and materials.

Low skill requirements: The operator's skill requirements are low and it is easier to get started.

Simple maintenance: Since there are no complex automation components, maintenance is relatively simple and repair costs are likely to be low.

The manual polishing machine is suitable for grinding and polishing various kinds of stone, such as granite, marble, tiles and so on. It is commonly used in stone processing plants, construction sites, home improvement and other places.

FAQ:

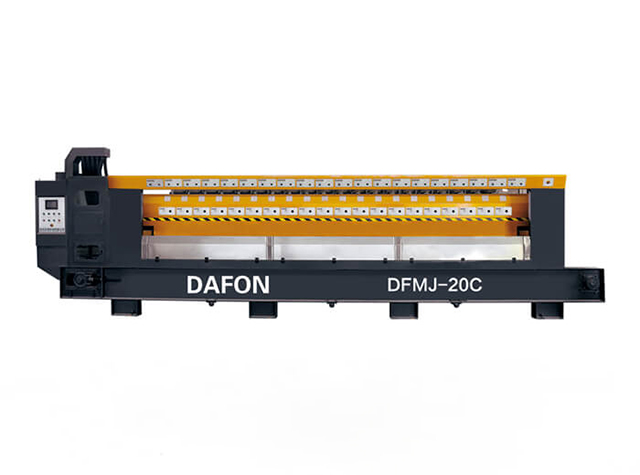

Introduction Technical Data Name Unit DFB-LM3700 Polishing pads pcs 8 Max. processing size mm 3700*2000*1500 Lifting stroke mm 1000 ...

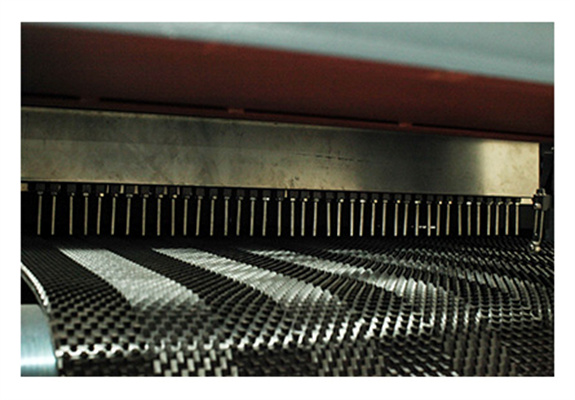

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu o...

Stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodgi...

Automatic Granite Polishing MachineTechnique Description : I.Suitable for the surface polishing granite/marble II.Using PLC intelligent control system and through the LCD touch s...

We offer online remote installation guidance for Manual Polishing Machine for Stone.And we also provideinstallation video and installation manual available....

We have extensive Manual Polishing Machine for Stone installation experience both at home and abroad and can provide our customers with suitable installation so...

Our company offers a one-to-one remote service. Ensuring a timely contact with our customers....

Improve production efficiency immediately and the automatic change heads function is very confinement2024-07-18

I've used this stone polisher machine for several months, and the results have been outstanding. It can automatic to change the polisher, so conveniently2024-07-15