Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-08-15

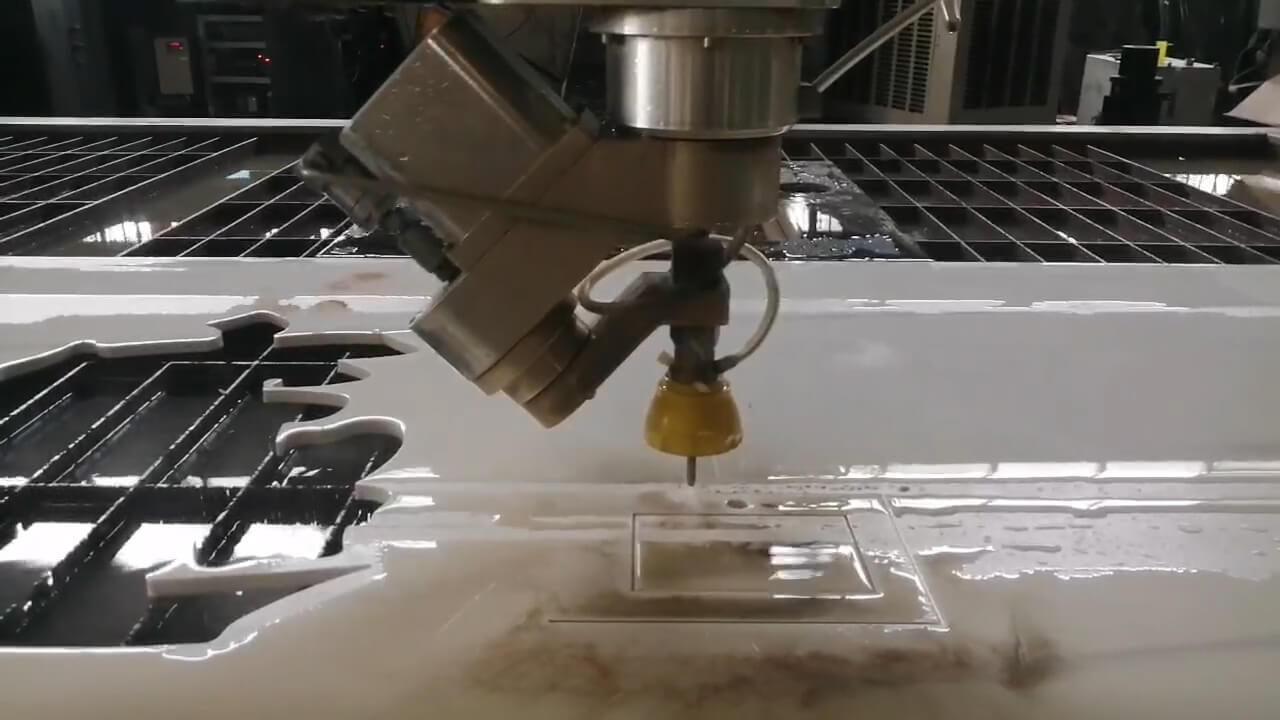

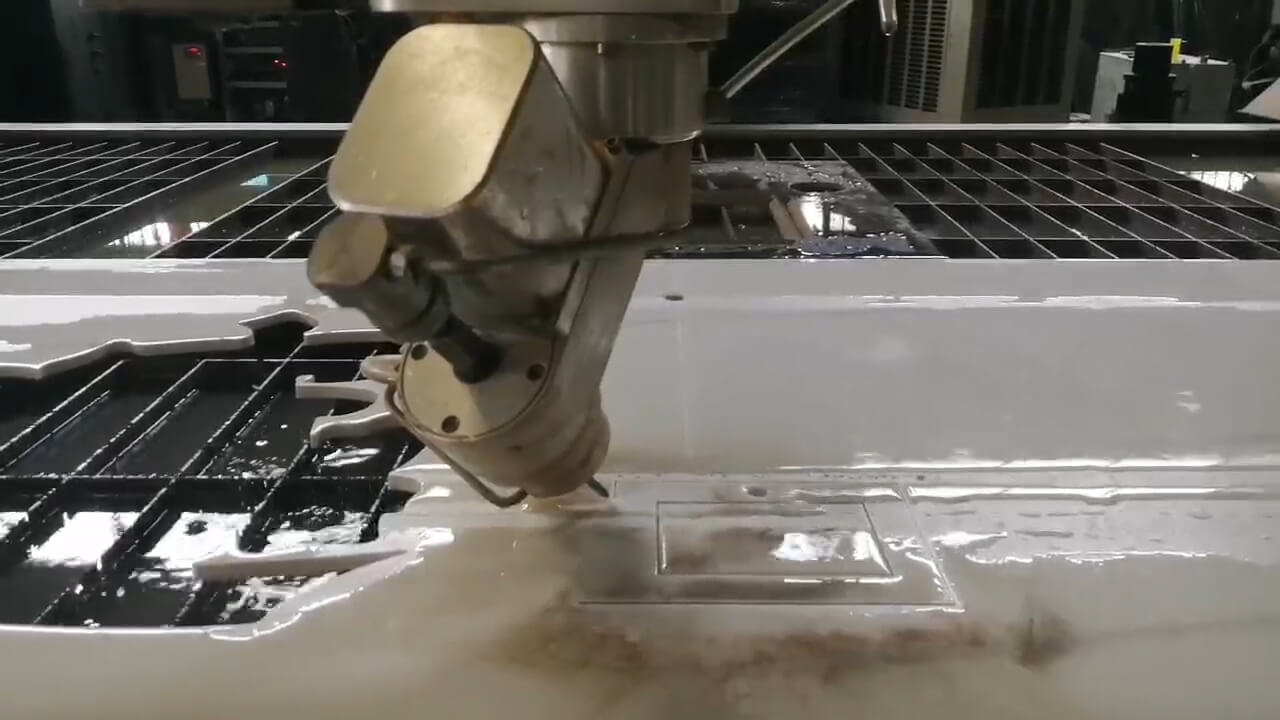

With the continuous advancement of industrial manufacturing technology, water jet cutting technology has been widely used in many fields. Among them, the 5-axis water jet cutting machine, with its multi-axis linkage function and high-precision cutting ability, has become an ideal tool for processing complex shapes and high-precision parts. This article will discuss in detail the functions, characteristics and applications of 5-axis water jet cutting machines in different fields.

1. High-precision cutting

The 5-axis water jet cutting machine can achieve the cutting of complex shapes and high-precision parts through five-axis linkage control. Its cutting accuracy can reach the micron level, which is especially important for industries with extremely high precision requirements such as aerospace and medical equipment. Whether it is metal or non-metal materials, the 5-axis water jet cutting machine can ensure smooth and burr-free cutting edges, reducing the need for subsequent grinding and processing.

2. Multi-material processing capabilities

The 5-axis water jet cutting machine can not only cut various metal materials, such as stainless steel, titanium alloy, aluminum alloy, etc., but also process non-metal materials such as composite materials, plastics, glass, and stone. Its wide range of material adaptability makes it widely used in multiple industries. For example, in automobile manufacturing, it can be used to cut body panels; in handicraft production, it can be used to engrave and cut complex patterns.

3. Efficient processing

Traditional cutting methods often require multiple steps and tools, while 5-axis water jet cutting machines can complete complex cutting tasks with one clamping, greatly improving production efficiency. In addition, the water jet cutting process does not require preheating, does not produce a heat-affected zone, avoids material deformation and annealing problems, and further improves processing efficiency and quality.

4. No heat-affected zone

Water jet cutting is a cold processing method that does not generate heat, which means that no heat-affected zone (HAZ) is generated on the material during the cutting process, and the material will not deform or harden due to heat. Therefore, it is very suitable for processing heat-sensitive materials such as metals, glass and composites.

5. Automation and continuous production

Modern 5-axis water jet cutting machines can usually be integrated with CNC systems to achieve automated operation. This not only improves production efficiency, but also reduces dependence on manual operation, thereby reducing production costs. In addition, the automation system can also achieve continuous production, further improving production capacity.

6. Reduce material waste

Due to its high precision and flexible cutting methods, the 5-axis water jet cutting machine can minimize material waste, especially when processing expensive materials. This advantage is more obvious. This also makes it excel in high-cost material processing, such as cutting marble, granite and metal parts.

Stone processing

In the field of stone processing, 5-axis water jet cutting machines are widely used in the cutting and shaping of natural stones such as marble and granite. It can cut complex stone shapes, make customized countertops, and design artistic stone patterns to meet the needs of high-end decoration and artistic stone carving.

Metal processing

In the field of metal processing, 5-axis water jet cutting machines can cut complex metal parts, especially in industries such as aerospace, automotive manufacturing and machinery manufacturing that require high-precision and complex parts. It can efficiently handle multi-angle metal cutting tasks.

Glass and ceramics

Glass and ceramic materials are fragile and heat-sensitive, and traditional thermal cutting methods may cause the material to break or deform. The cold cutting technology of the 5-axis water jet cutting machine can avoid these problems and ensure high-precision cutting effects without heat damage. Therefore, it is widely used in architectural glass, decorative glass, ceramic products and other fields.

Composite materials

The structure of composite materials is complex, and conventional cutting methods are difficult to achieve high-precision processing. Due to its multi-axis linkage and strong material adaptability, the 5-axis water jet cutting machine has become an ideal tool for processing composite materials. It is widely used in wind power generation, shipbuilding, automotive lightweight parts and other fields.

Summary

The 5-axis water jet cutting machine has become an indispensable processing tool in modern manufacturing with its excellent multi-dimensional cutting ability, high precision and material adaptability. Whether in stone processing, metal cutting or in the processing of glass, ceramics and composite materials, the 5-axis water jet cutting machine has demonstrated its powerful functions and broad application prospects. With the continuous advancement of automation technology, the 5-axis water jet cutting machine will play a greater role in more fields and bring more efficient and precise processing solutions to the manufacturing industry.