Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2022-11-30

In the early days, the kerb stones were not demanding, the size requirements were not strict, and the processing technology was simple cutting and forming. And nowadays, the production of kerb stone is more and more pursuing characteristics, and the processing technology is more and more complicated. Not only cutting and forming, strict dimensional error requirements, now the surface treatment process also towards diversified ways. Some require two-sided polished, some require six-sided sandblasting, some require four-sided fire, some require chamfering large angle treatment, more and more processing technology in the test of the stone business production capacity.

Then in order to meet the production needs, stone enterprises naturally have to choose advanced equipment kerbstone cutting machine for processing production. The following is an introduction to the kerb stone two-sided grinding process line equipment, and production process.

The first choice of stone block cutting machine for the cutting of the barren material, cut into roadside stone semi-finished products.The machine adopts PLC programmable control and man-machine operation interface, supplemented by ultra-bright precision rotary encoder for slice, left and right knife using frequency converter control, according to the stone material for speed regulation, up and down lift using hydraulic lift, combined with chrome-plated guide pillar plus wear-resistant guide bush, with small clearance, wear-resistant and beautiful, and in the guide bush design multi-layer seal, waterproof, dustproof and oil leakage, improve service life, front and rear slice using high-precision The key parts are imported high quality spare parts, and the barren material can be placed directly on the ground, saving the cost of cart and its maintenance; thus it has the advantages of high cutting efficiency, high precision of slice, good flatness of the cut plate, high stability, easy operation, etc. It is especially suitable for the cutting of high value granite and marble barren material.

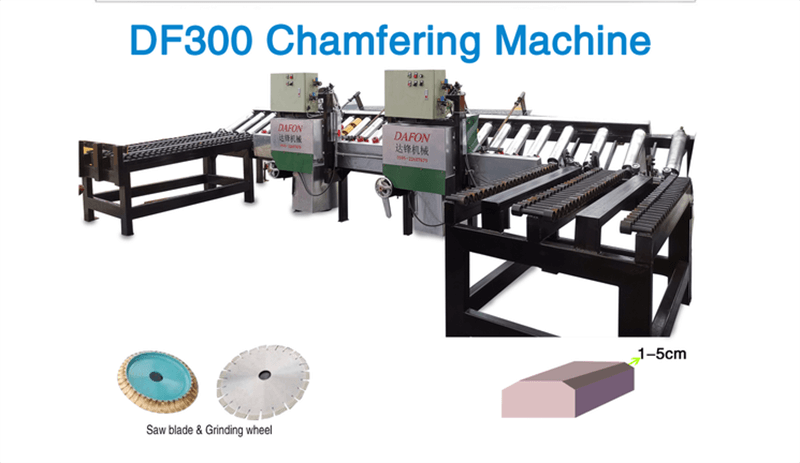

After cutting by stone block cutting machine, one worker uploads the material to the curbstone slicing machine through the line crane, another worker lifts the cut curbstone on the curbstone single knife length setting machine to the top of the curbstone grinding machine for grinding and chamfering through the line crane, and the third worker unloads and packs the material through the small crane behind the chamfering grinding machine.Kerbstone cutting machine The whole process only needs 3 workers to operate, which greatly saves labor cost. The whole productive continuity is through and stable.