Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2022-11-28

Hand crank granite stone cutting machine has the advantages of easy and quick operation, high cutting efficiency, high automation and good processing quality, which is still widely used in the stone industry. The machine is mainly applicable to cutting and chamfering of granite and marble plates. In the chamfering, the table is installed to pour - the angle of the bracket, the plate on the bracket, the saw blade for vertical cutting, that is, the corresponding chamfering can be processed. And some equipment can rotate the spindle head and chamfer directly.

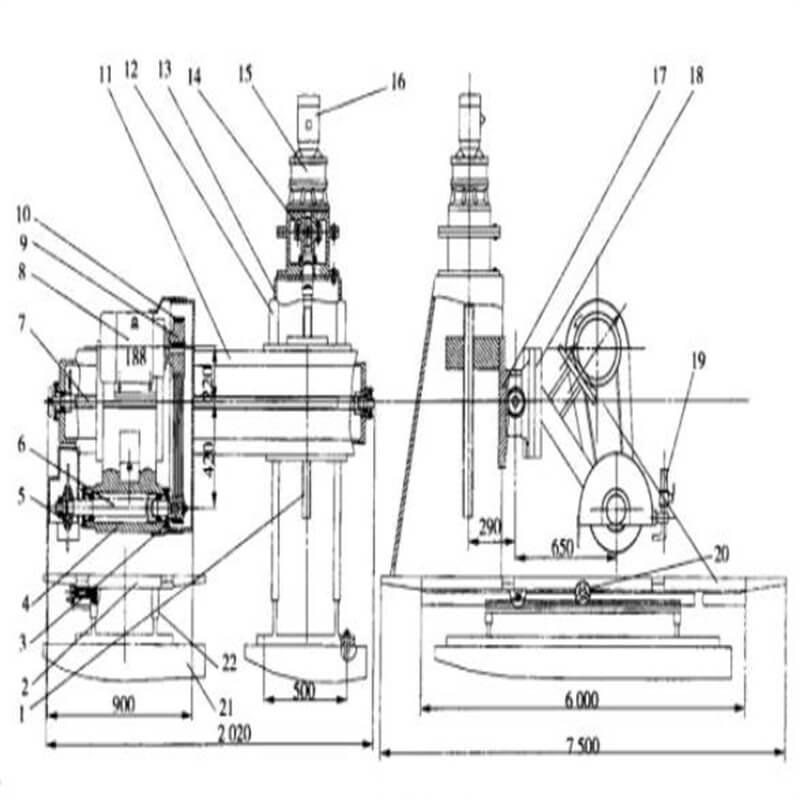

It is mainly composed of the longitudinal movement system of the head, the transverse movement part, the main cutting part and the table movement system. The main motion of the machine is the rotary motion of the diamond saw blade on the spindle and the feeding motion of the table along the cutting direction during the cutting process, so as to realize the continuous cutting of the plate. small granite stone cutting machine's transverse movement mechanism is designed to facilitate the cutting of different widths of plates and to meet different feeds during the cutting.

3.The hand crank small stone cutting machine transverse moving part of the working principle

The operation of granite stone cutting machine's horizontal movement is by manual operation, the basic route is that the worker drives the horizontal screw through the rocker, the screw drives the diamond saw blade to do horizontal movement through the nut. The vertical movement is driven by the motor, the motor drives the reducer, and through the coupling, the rotary motion is transmitted to the longitudinal screw, and the screw drives the transverse guide (diamond saw blade is installed on the transverse guide) to do up and down movement through the screw nut.