Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-10-11

In the stone slab manufacturing industry, the handling of heavy stone slabs is a crucial yet challenging task. Traditionally, the loading and unloading of stone slabs have been labor-intensive processes, requiring manual handling by workers. However, with advancements in technology, automatic loaders and unloaders are transforming this part of the manufacturing process, greatly improving efficiency and safety.

What Are Automatic Loaders and Unloaders?

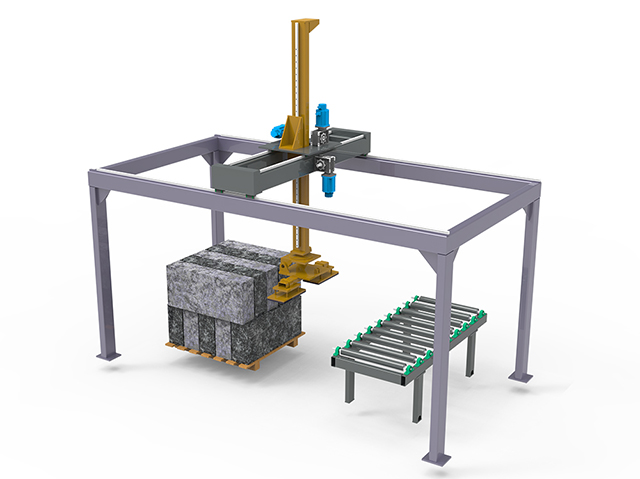

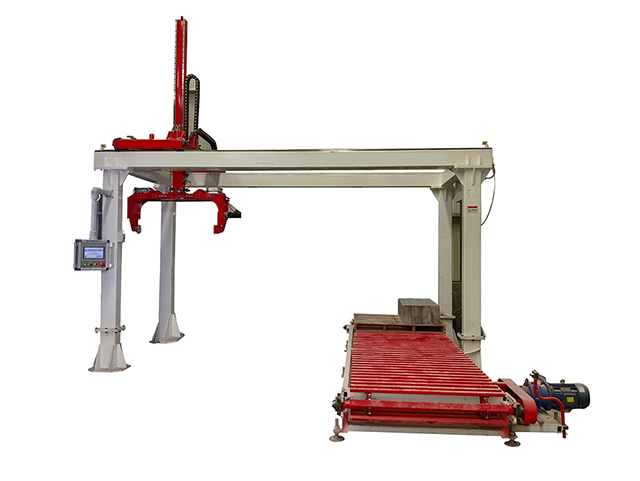

Automatic loaders and unloaders are machines designed to automate the movement of stone slabs during the manufacturing process. These machines can handle various stone materials, including granite, marble, and quartz. They play a key role in moving slabs from one stage of processing to another, such as from the cutting machine to the polishing or storage area.

By using suction cups, grippers, or mechanical arms, the loaders and unloaders ensure that slabs are handled delicately without causing surface damage, cracks, or breakage. The machines can be integrated with other equipment, such as CNC machines, bridge saws, and polishing lines, to create a fully automated production process.

Benefits of Automatic Loaders and Unloaders

Increased Efficiency:

Manual loading and unloading are time-consuming and require multiple workers, especially when handling large and heavy stone slabs. With automation, the process becomes faster and more precise, leading to higher production rates. Automatic loaders and unloaders can work continuously without breaks, boosting productivity and streamlining operations.

Improved Safety:

Handling heavy stone slabs manually can be dangerous, as it poses risks of injury, especially to workers' backs and hands. Automatic loaders and unloaders reduce the need for manual handling, thus minimizing the potential for workplace injuries. They are equipped with safety sensors and mechanisms to prevent accidents during operation.

Cost Savings:

While the initial investment in automatic loaders and unloaders may seem significant, the long-term benefits outweigh the costs. By reducing the need for manual labor, companies can cut down on labor costs. Additionally, the increased efficiency of the automated system leads to faster production cycles, which contributes to higher profitability.

Consistent Product Quality:

Stone slabs require careful handling to avoid surface damage or chips, which can occur during manual loading and unloading. Automatic loaders and unloaders provide consistent handling, ensuring that the slabs remain intact and free from defects. This helps maintain the high-quality standards of the stone products.

Optimized Factory Space:

Automated loaders and unloaders are compact and can be integrated into existing production lines without requiring large amounts of space. This is especially beneficial for manufacturers with limited factory space who still need to increase production capacity.

Types of Automatic Loaders and Unloaders

Suction-Based Systems:

These loaders use vacuum suction cups to lift and move stone slabs. Suction-based systems are commonly used for delicate materials like marble and quartz, as they provide gentle handling without scratching or damaging the surface.

Mechanical Grippers:

These loaders employ mechanical arms with clamps or grippers to pick up and transport slabs. They are suitable for handling heavy-duty materials such as granite and are often used in conjunction with CNC machines or bridge saws.

Robotic Systems:

For fully automated factories, robotic loaders and unloaders are becoming increasingly popular. These systems are equipped with AI and sensors to precisely handle stone slabs, optimizing speed and efficiency. Robotic systems are flexible and can be programmed to handle different sizes and types of stone.

The Future of Automation in the Stone Industry

As the stone industry continues to evolve, the adoption of automated machinery is becoming a necessity for manufacturers looking to stay competitive. Automation not only improves efficiency but also enhances product quality and safety, reducing operational costs over time. Automatic loaders and unloaders are just one part of this trend toward fully automated production lines, where technology plays a vital role in driving success.

In conclusion, automatic loaders and unloaders have revolutionized the stone slab manufacturing industry by offering a safer, more efficient, and cost-effective solution for handling heavy stone materials. As more manufacturers invest in automation, these machines will continue to be an essential part of modern stone processing.