Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-10-10

Introduction

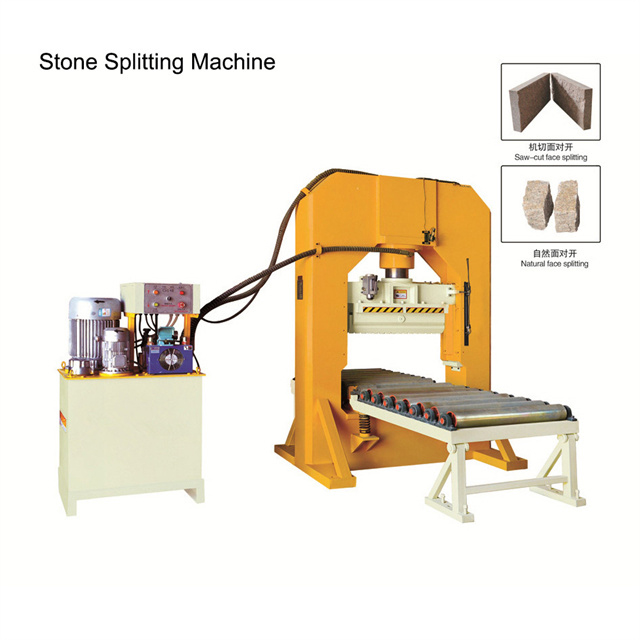

In the world of stone processing, maintaining the natural beauty of stones while achieving the desired texture and shape is often a challenge. One machine that has revolutionized the industry, particularly for producing decorative stone finishes, is the Mushroom Stone Splitting Machine. This specialized machine is designed to create a rugged, natural-looking split face finish, perfect for both indoor and outdoor architectural applications. Let's explore how this machine works and the benefits it brings to the stone industry.

The mushroom stone splitting machine is a highly efficient tool used to process natural stones such as granite, marble, limestone, and sandstone. Its primary function is to split stones into desired sizes and shapes while giving them a natural "mushroom" or split-face finish. This rough, textured finish resembles stones that have been naturally weathered, making it ideal for rustic and traditional architectural styles.

The machine operates using a hydraulic system that applies high pressure to split stones precisely and quickly. This allows stone manufacturers to meet various aesthetic and structural demands for landscaping, wall cladding, paving, and other decorative uses.

Precision and Efficiency: One of the standout features of the mushroom stone splitting machine is its ability to split stones with accuracy, minimizing waste. The hydraulic pressure ensures that each stone is split evenly, reducing the need for post-processing.

Customization: The machine can handle different stone sizes, thicknesses, and hardness levels. Whether you are working with soft limestone or harder granite, the machine can be adjusted to split each material effectively, providing a consistent finish.

High Production Capacity: Designed for mass production, the machine can process a large quantity of stone within a short time. This significantly increases productivity and reduces labor costs compared to manual splitting.

Durable Construction: These machines are built with high-strength materials to withstand heavy-duty usage, ensuring long service life and minimal maintenance requirements.

Architectural Wall Cladding: The split-face finish is widely used in exterior and interior wall cladding. It adds a rustic charm to buildings, providing an earthy and timeless look. The machine can create uniform pieces that are perfect for large-scale cladding projects.

Garden and Landscape Design: Mushroom stones are often used in landscaping to create natural-looking retaining walls, walkways, and garden decorations. The stone’s rough finish gives it a distinctive, organic appearance that blends well with outdoor environments.

Paving Stones: For pathways, driveways, and patios, mushroom-split stones offer an attractive and durable surface. The natural finish not only enhances the aesthetic appeal but also provides a non-slip texture, making it ideal for outdoor spaces.

Enhanced Aesthetics: The natural, rugged appearance of mushroom stones adds value to any construction or landscaping project. The machine helps maintain the stone’s natural beauty while enhancing its usability.

Cost Efficiency: By automating the splitting process, stone manufacturers can significantly cut down on labor costs and time, increasing overall productivity. This efficiency translates to lower production costs and higher profits for businesses.

Sustainability: The precise cutting process minimizes waste, making it an eco-friendly option. Stone off-cuts can also be repurposed, further reducing material wastage.

The mushroom stone splitting machine has become a valuable asset in the stone industry, helping businesses create high-quality, naturally finished stone products efficiently and consistently. With its ability to produce a rustic, split-face finish, this machine has expanded the design possibilities for architects, builders, and landscape designers. By investing in this machine, stone manufacturers can not only increase their production capacity but also elevate the aesthetic quality of their products, making it an essential tool for modern stone processing.