Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-08-09

What is the best bridge saw?

Best Bridge Saw: A Matter of Needs

Determining the "best" bridge saw depends largely on your specific needs. Factors like budget, material type, cutting depth, and frequency of use will influence your choice.

Factors to Consider

Material: What kind of materials will you be cutting? Different materials require different blade types and cutting speeds.

Cut Depth: How thick are the materials you'll be working with? The saw's cutting depth must accommodate your needs.

Cutting Precision: Look for high precision if your products require intricate cuts.

Cut Length: What is the maximum length of material you need to cut?

Budget: Balance your needs with the available budget.

Automation: Higher automation can reduce labor costs and improve consistency.

Durability: A durable saw will offer a better ROI over time.

Types of Bridge Saws

Before diving into specific models, it's helpful to understand the primary types:

Manual Bridge Saws: Ideal for occasional use and smaller projects. They are typically less expensive but require more physical effort.

Semi-Automatic Bridge Saws: Offer some automated features, such as motorized cutting head movement, making them easier to operate.

CNC Bridge Saws: Highly automated for precise and complex cuts, often used in large-scale production environments.

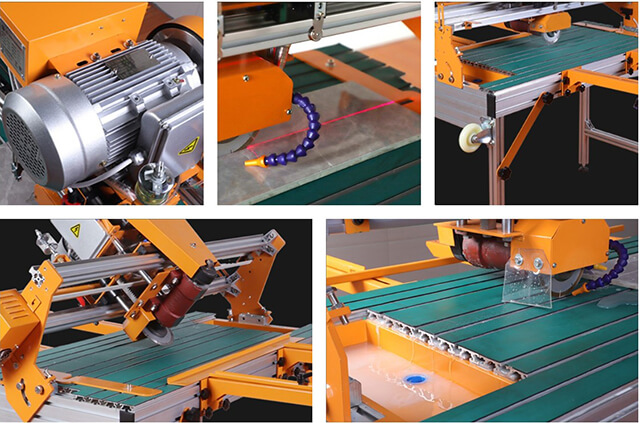

Dafon CNC Bridge Saw

Key Features: High precision, user-friendly interface, efficient cutting, durable construction.

Ideal For: Medium to large-scale stone processing, especially for granite and marble slabs.

Benefits: Delivers excellent ROI due to its efficiency and long lifespan.

a highly efficient and space-saving CNC bridge saw like those from Dafon or similar brands would be ideal. These machines provide the necessary precision and reliability while addressing space constraints.

A bridge tile saw is a specialized cutting tool used primarily for cutting tiles made of ceramic, porcelain, marble, granite, and other types of stone. It is called a "bridge" saw because of its design, where the cutting head moves along a bridge-like structure that spans the work area. This allows for precise and straight cuts, making it ideal for professional tile installers and stone fabricators.

Uses of a Bridge Tile Saw:

Cutting Tiles to Size: It is used to cut tiles to specific sizes, essential when tiles need to fit into a particular space or design layout.

Creating Straight and Angled Cuts: The bridge tile saw can make straight cuts, miter cuts, and even bevel cuts, providing flexibility in tile installation projects.

Cutting Thick or Large Tiles: Due to its sturdy construction and powerful motor, a bridge tile saw can handle thicker and larger tiles that might be difficult to cut with a standard tile cutter.

Precision and Accuracy: The guided rail system ensures that cuts are precise and clean, reducing the likelihood of chipping or breaking the tiles.

Wet Cutting: Many bridge tile saws have water cooling systems that keep the blade cool during cutting, reduce dust, and minimize the risk of damaging the tiles.

Versatility: It is also used for cutting stone slabs, making it a versatile tool for both tile and stonework.

This tool is especially useful for large-scale tile installation projects where accuracy, speed, and the ability to cut large tiles are important.

A tile saw and a wet tile saw are both used for cutting tiles, but they differ primarily in how they manage the cutting process:

1. Tile Saw

Basic Functionality: A tile saw is a general term for any saw designed to cut tiles. It can be manual or powered.

Types: Tile saws can be manual (like a tile cutter with a scoring wheel) or powered (like a circular saw with a diamond blade).

Cutting Dry: Some tile saws can operate without water, cutting tiles dry. However, cutting dry may produce more dust and heat, which can lead to a rougher cut or damage to the tile.

2. Wet Tile Saw

Integrated Water System: A wet tile saw specifically refers to a powered saw that uses water to cool the blade and reduce dust while cutting. It typically has a water reservoir or connection to a water source.

Smooth Cuts: The water helps to lubricate the cutting surface, leading to cleaner and more precise cuts, especially in harder materials like porcelain or natural stone.

Dust Control: The water minimizes airborne dust, making the cutting process safer and cleaner.

Heat Reduction: The water cooling system reduces heat build-up on the blade, prolonging its life and preventing the tile from cracking due to heat stress.

Key Differences:

Water Use: The most significant difference is that a wet tile saw uses water to cool the blade and control dust, while a regular tile saw may not.

Cut Quality and Efficiency: Wet tile saws are generally better for making precise, clean cuts on harder materials and for larger, more continuous cutting tasks.

Dust and Heat Management: Wet tile saws manage dust and heat more effectively, making them suitable for professional or heavy-duty use.

In summary, while both tools can cut tiles, a wet tile saw is specifically designed to offer more precise cuts, better dust control, and cooler blade operation, making it preferable for professional tile work.

Bridge tile saws can offer several advantages over standard tile saws and wet tile saws, especially for specific applications:

Advantages of Bridge Tile Saws:

Precision and Accuracy:

Stable Cutting: The bridge design provides a stable framework that supports the cutting head, leading to more accurate and straight cuts.

Consistent Performance: They are often used in professional settings where precision is crucial, such as for large-format tiles or intricate patterns.

Large Cutting Capacity:

Handling Large Tiles: Bridge tile saws can accommodate larger tiles or slabs due to their larger cutting surface and adjustable cutting bed.

Versatile Size: They can handle both small and large materials, making them versatile for various tile sizes.

Power and Efficiency:

Powerful Motors: These saws typically have powerful motors that can handle heavy-duty cutting tasks with ease.

Efficiency: The design allows for efficient cutting of multiple tiles or large pieces with less manual effort.

Built-In Water System:

Dust Control: Many bridge tile saws come with built-in water cooling systems, similar to wet tile saws, which helps in controlling dust and reducing heat.

Durability:

Heavy-Duty Construction: They are usually built with robust materials and components, making them durable and suitable for high-volume use.

Considerations:

Cost:

Higher Investment: Bridge tile saws tend to be more expensive than standard tile saws due to their advanced features and larger size.

Space Requirements:

Larger Footprint: They require more space in a workshop or job site because of their size and the need for a stable setup.

Complexity:

Operating : The setup and operation may be more complex compared to simpler tile saws, which might require additional training or experience.

Bridge tile saws are often better for professional and high-volume tile cutting operations due to their precision, capacity, and durability. They excel in cutting larger tiles or slabs and offer consistent, high-quality results. However, they come with a higher price tag and require more space, so whether they are the best choice depends on your specific needs, budget, and workspace.