Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-08-08

A block cutting machine is an industrial tool designed to cut large blocks of stone into smaller, desired shapes and sizes. This process is crucial in the stone industry for producing various products such as slabs, tiles, and construction materials.

Originally, stone cutting was a labor-intensive process relying on manual tools. However, the introduction of mechanical cutting machines in the 19th century revolutionized the industry, enabling more efficient and precise cutting. Today, advanced technologies have led to the development of automated and CNC block cutting machines that deliver exceptional accuracy and speed.

A stone cutting machine can be referred to by several names depending on its specific type and functionality. Here are the common types of stone cutting machines:

Single Blade Block Cutting Machines

Single Blade Block Cutting Machines are designed for cutting large stone blocks into slabs or smaller pieces using a single blade. These machines are often used in the stone processing industry for their simplicity and effectiveness in producing precise cuts.

Multi-Blade Block Cutting Machines

Multi-blade block cutting machines are industrial workhorses designed to efficiently transform large stone blocks into multiple slabs simultaneously. These machines are equipped with several saw blades that operate in parallel, significantly increasing production output compared to single-blade machines.

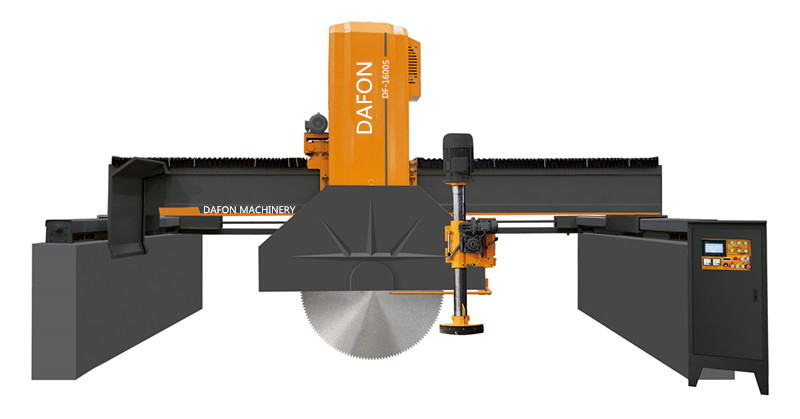

Bridge Block Cutting Machines

Bridge Block Cutting Machines are specialized stone cutting machines characterized by their bridge-like structure. These machines are designed to provide stability and precision in cutting large stone blocks into slabs or other desired shapes.

Cement Block Cutting Machines

These are specifically designed for cutting cement blocks. adopting advanced cutting technology and automatic control system, featuring simple operation, fast cutting speed, smooth cutting and high precision, suitable for cutting concrete blocks, ceramic blocks, cement foam EPS foam and other new materials

Vertical-Horizontal Stone Block Cutter

Vertical-horizontal stone Block Cutters are advanced machines designed to cut stone blocks in both vertical and horizontal directions. This dual capability allows for versatile cutting, saving edging cutting the step, more efficient than the multi-blade block cutting machine

The process of block cutting involves several steps to ensure the efficient and accurate cutting of stone blocks into slabs or other desired shapes. Here's an overview of the process:

A. Initial Setup and Calibration

Machine Preparation: Ensure that the cutting machine, such as a CNC bridge saw, is properly installed and ready for operation.

Tool Selection: Choose the appropriate cutting tools (e.g., diamond blades) based on the type of stone being processed.

Calibration: Calibrate the machine to ensure precise measurements and cutting angles. This involves setting the cutting parameters, such as speed, depth, and blade rotation.

B. Loading the Stone Block

Positioning: Place the stone block on the machine's cutting table or platform. Use clamps or other securing mechanisms to keep the block stable during the cutting process.

Alignment: Align the stone block with the cutting tools and ensure it is positioned correctly according to the desired cut patterns.

C. Cutting Process

Horizontal and Vertical Cuts:

Horizontal Cuts: The machine makes horizontal cuts along the length or width of the stone block. These cuts can be adjusted based on the thickness of the slabs needed.

Vertical Cuts: After completing the horizontal cuts, the machine makes vertical cuts to separate the slabs or sections from the block.

Precision and Accuracy:

Control Systems: Utilize computer-controlled systems to maintain high precision and accuracy during the cutting process.

Monitoring: Continuously monitor the cutting process to ensure that the cuts are consistent and meet the required specifications.

Adjustments: Make any necessary adjustments to the cutting parameters to address any issues or variations in the stone block.

D. Unloading the Cut Stone

Removal: Once the cutting process is complete, carefully remove the cut stone slabs or sections from the machine.

Inspection: Inspect the cut pieces for quality and accuracy, checking for any defects or irregularities.

Handling: Use appropriate equipment to safely handle and transport the cut stone to the next stage of processing or to storage.

By following these steps, the block cutting process ensures that stone blocks are efficiently and accurately cut into slabs or other desired shapes, ready for further processing or use.

Initial Setup and Calibration

Before cutting, the machine needs to be set up and calibrated. This involves adjusting the cutting blade, setting the parameters, and ensuring the stone block is securely positioned.

Loading the Stone Block

The stone block is loaded onto the machine, either manually or using lifting equipment. Proper alignment is crucial for achieving accurate cuts.

Cutting Process

The cutting process involves both horizontal and vertical cuts, depending on the desired final product. CNC machines follow programmed instructions to execute intricate patterns and precise dimensions.

Unloading the Cut Stone

Once the cutting is complete, the finished stone pieces are unloaded and inspected for quality. They may undergo further processing, such as polishing or edge finishing.

The price of a block cutting machine can vary widely depending on several factors, including the type of machine, its features, the manufacturer, and the specific requirements of the user. Here are some general price ranges for different types of block cutting machines:

· Type of Stone: Machines designed for cutting harder stones like granite or marble might be more expensive due to the need for more robust construction and powerful cutting tools.

· Automation Level: Machines with higher levels of automation, such as CNC controls, automatic tool changers, and integrated software, tend to be more expensive.

· Cutting Capacity: Larger machines capable of handling bigger stone blocks and higher cutting volumes typically cost more.

· Brand and Manufacturer: Reputable brands and manufacturers often command higher prices due to their reliability, customer support, and advanced technology.

· Additional Features: Features like multi-blade configurations, water cooling systems, and dust extraction systems can add to the cost.

Choosing the right block cutting machine is crucial to ensure efficiency, precision, and cost-effectiveness. Here’s a detailed guide on how to select the appropriate machine based on various factors:

1. Material Type and Hardness

Material Compatibility: Ensure the machine is suitable for the type of stone you intend to cut, such as granite, marble, limestone, or other materials.

Hardness Considerations: Harder materials like granite require more robust and powerful machines with diamond blades or other specialized cutting tools.

2. Production Volume

Capacity Needs: Assess your production volume to choose a machine that can handle the required throughput. Higher production volumes may necessitate a machine with faster cutting speeds and larger capacity.

Scalability: Consider whether the machine can scale with your business growth. A machine with higher capacity might be more cost-effective in the long run.

3. Precision and Quality Requirements

Cutting Accuracy: Evaluate the machine’s ability to deliver precise and accurate cuts, which is essential for maintaining high-quality standards.

Consistency: Ensure the machine can produce consistent results across multiple cuts and over extended periods of operation.

4. Budget and Cost Considerations

Initial Investment: Determine your budget for purchasing the machine, considering both the initial cost and any additional expenses for installation and setup.

Operational Costs: Factor in long-term operational costs, including maintenance, repairs, power consumption, and the cost of consumables like blades and cooling fluids.

Return on Investment (ROI): Calculate the potential ROI by comparing the machine’s cost with the expected productivity gains and cost savings.

5. Space and Infrastructure Requirements

Physical Space: Ensure you have sufficient space in your facility to accommodate the machine, including room for loading and unloading stone blocks.

Infrastructure: Check that your facility has the necessary infrastructure, such as power supply, water supply for cooling, and proper ventilation or dust extraction systems.

Installation Needs: Consider any additional requirements for installation, such as foundation work or special floor reinforcement.

Additional Considerations:

Ease of Use: Look for machines with user-friendly interfaces and controls to minimize training time and reduce the likelihood of operator errors.

Automation and Technology: Advanced features like CNC controls, automation, and integration with software can enhance productivity and reduce labor costs.

Brand and Support: Choose reputable brands known for quality and reliability. Also, consider the availability of customer support, spare parts, and after-sales service.

Future-proofing: Consider the machine's flexibility and ability to adapt to future technological advancements or changes in your production needs.

Conclusion

By carefully evaluating these factors, you can select a block cutting machine that meets your specific requirements, ensuring efficient and high-quality production while keeping costs manageable. Always consult with manufacturers and industry experts to get tailored advice and recommendations based on your unique needs.