Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-07-08

Ⅰ.Introduction

Stone is the most suitable material for kitchen countertops. Stone countertops have the characteristics of beautiful appearance, high hardness and resistance to deformation.

Therefore, the use of stone in countertops is very common. Especially granite made into kitchen countertops provides an unusual and long-term home decoration solution. At this stage, it is still the most perfect solution on the market. Granite is one of the most delicate natural stones for kitchen countertops. The most important benefit of granite kitchen countertops is that no two granites are exactly alike, so you can create an unusual and luxurious kitchen. There is no doubt that with good care, the good-looking appearance of granite kitchen countertops will not fade over time.

1. Heat resistance: Granite has excellent heat resistance and heat dissipation. Placing the heated pot directly on the countertop will not leave any traces; nor will bubbles or cracks appear on the countertop due to excessive temperature differences.

2. Resistance: Granite has basically no pores and is not prone to bacteria, dirt, mold, mildew and other problems.

3. Hardness: The hardness of granite is second only to diamond in nature, so granite countertops are not prone to scratches and are hard but not brittle.

4. Stability: Granite is stable in nature, non-conductive, non-magnetic, acid and alkali resistant, corrosion resistant, has good shock absorption effect and long service life.

5. Conducive to removal: Granite kitchen countertop care is very simple. You only need to master some basic knowledge to easily achieve the purpose of care.

The role of precision and quality in cutting granite countertops.

In the realm of high-end kitchen and bathroom design, granite countertops reign supreme. Their inherent beauty, exceptional durability, and timeless appeal make them a coveted choice for discerning homeowners. However, to unlock the full potential of this natural stone, achieving the highest standards of precision and quality during the fabrication process is absolutely crucial.

Granite countertops elevate kitchens and bathrooms with their elegance and durability. But to truly shine, precision and quality cutting are essential.

Precision cuts ensure visual harmony by respecting the natural beauty of granite's patterns and enabling seamless integration with appliances and sinks. It also eliminates safety hazards from uneven edges.

Quality cutting maximizes material use, minimizes installation headaches, and creates a long-lasting investment that enhances your home's value.

Advanced machinery and skilled fabricators achieve these goals. The result? A stunning, functional, and safe granite countertop that elevates your space.

II. Types of Machines Used to Cut Granite Countertops

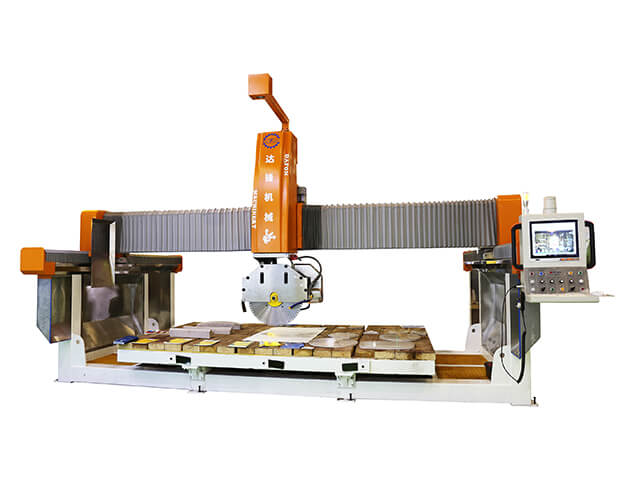

CNC bridge saws are more automatic rather than infrared bridge cutters, which use a CNC system to control cutting, and precisely cut granite countertops according to a digital program.

Precision: Adopting CNC systems makes the cutting accuracy

Automation: These saws automate the cutting process, minimizing human error and ensuring consistent results.

Efficiency: CNC Bridge Saws can handle complex cuts and repetitive tasks quickly, boosting production efficiency.

CNC Bridge Saws excel in fabricating intricate countertop shapes, creating precise cutouts for sinks and cooktops, and achieving clean, straight edges on granite with minimal chipping.

Water Jet Cutters utilize a high-pressure stream of water mixed with abrasive garnet particles to cut granite.

Precision: Water Jet Cutters can achieve incredibly intricate and detailed cuts on granite.

Minimal Heat Generation: They minimize the risk of heat damage to the granite, which can cause cracks or discoloration.

Because of the high stability of the water jet cutter cutting process, the cut granite has a smooth cut, and can increase the smooth effect of the plate in the ceramics cut by the straight or curved bearing, increase the high-pressure centrifugal rotation speed of the bearing, and can complete any cutting pattern on time in particularly delicate hand-carving.

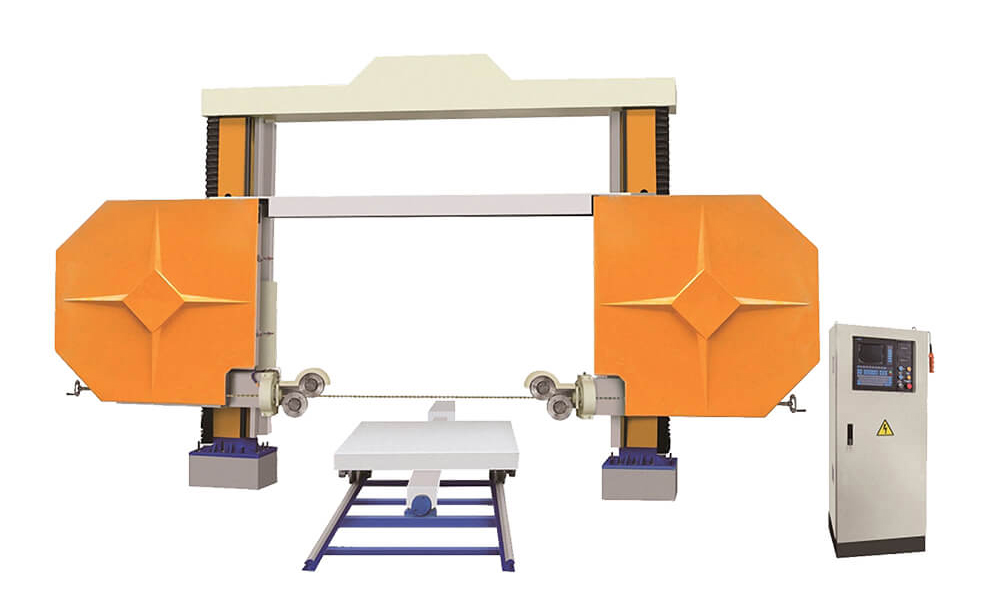

Diamond Wire Saws employ a continuous diamond-wire loop to cut large blocks of granite into slabs or desired shapes. slicing through the granite with precision.

Precision: Diamond Wire Saws can achieve highly precise cuts on large granite blocks.

Reduced Waste: They minimize material waste during the initial cutting stage compared to traditional sawing methods.

Diamond Wire Saws are primarily used in granite quarries and fabrication shops to cut large granite blocks into manageable slabs or specific shapes for countertops and other applications.

III. How These Machines Work

CNC machining is an automated machining method with the characteristics of high efficiency, high precision and high flexibility. It inputs the CNC program of the plate to be processed into the machine tool, so that the machine tool can automatically process products that meet the expected plan under the control of these data.

The working principle of water jet cutting is to mix ordinary water with specific iron sand, and then spray a water arrow through the water nozzle after being pressurized by an ultra-high pressure booster. The speed of the water jet can reach 900 meters per second (about 3 times the speed of sound). It is precisely such a fast speed that makes the water jet as sharp as a knife and can easily cut various rock slabs.

It mainly relies on a high-speed rotating drive wheel to drive this diamond rope to rotate at high speed. When the diamond rope comes into contact with the material, it will be able to quickly cut through the material due to the high speed rotation of the rope and the sharpness of the diamond particles. Moreover, due to the flexibility of the diamond rope, it can be adapted to various shapes of cutting needs, whether it is a straight line or a curve, it does not matter!

IV. Factors to Consider When Choosing a Granite Cutting Machine

Stone cutting machines are a type of tool product that is often used in the processing of modern building stones. However, the quality of granite kitchen countertop processing depends in part on the quality of the stone cutting machines used.

A. Precision and Accuracy

You want a machine with guides and easy controls to make straight,precision cuts. The ability to adjust the cutting depth and angle is important for countertops and fancy shapes.

B. Speed and Efficiency

A strong motor helps you cut through granite quickly, especially thick or hard slabs. Variable speed lets you adjust for the job - slow for detailed cuts, fast for straight lines in granite.

C. Durability and Maintenance

To ensure precise cutting with minimal vibration, prioritize machines built with high-grade steel frames, industrial-grade components, and aprovidewell-supported preventative maintenanceservice.

D. Cost and Return on Investment

When choosing a granite cutting machine, consider not just upfront cost, but also long-term factors like maintenance, energy use, blade wear, production speed, scalability, downtime minimization, and readily available parts.

E. Compatibility with Various Granite Types

Use high-quality, wet-cutting diamond blades designed for granite to optimize cutting performance and blade life.

V. Case Study: Dafon Machinery

· Overview of Dafon Machinery's CNC bridge saws

Dafon Machinery is a leading manufacturer of stone processing machinery in China, specializing in CNC bridge saws. Their products are renowned for their precision, efficiency, and durability, making them a popular choice for stone fabricators worldwide.

Dafon's CNC bridge saws are designed for precise and efficient cutting of marble, granite, and other natural stone materials. They feature a robust gantry structure, high-precision linear guides, and powerful cutting motors to ensure accurate and consistent results.

· Success stories and testimonials from customers.

Dafon Machinery has a long history of satisfied customers, many of whom have provided glowing testimonials about their products. you can check ourcase andevaluation on products

"Dafon's CNC bridge saw change in our business. It has allowed us to increase our production output and improve the quality of our cuts." - the customer's feedback

· Analysis of the return on investment for using Dafon Machinery’s products.

The ROI for using Dafon Machinery's products can be significant for stone fabricators and other businesses that work with natural stone. Here are some of the potential benefits:

Increased productivity: the CNC bridge saw machine can help the stone processing factory cut stones faster and more accurately, which can lead to increased production output.

Improved quality: Dafon's machines produce high-quality cuts that meet the demands of even the most discerning customers.

Reduced waste: minimize waste by producing precise cuts, which can save businesses money on material costs.

VI. Conclusion

Granite countertops are popular for their durability and beautiful appearance, but traditional cutting processes have many limitations. In recent years, granite cutting technology has been continuously innovating and developing towards a more efficient, more precise and more environmentally friendly direction.

Emphasis on the importance of choosing the right machine for cutting granite countertops.

CNC bridge saw has fast cutting speed and high precision, and can achieve complex shape cutting, but it also requires a high level of technical skills from the operator

Diamond Wire Saws: Using fine diamond wire for cutting, it can achieve processing of any curve, which is very suitable for creating unique granite countertops. However, wire cutting is relatively inefficient and requires a high level of technical skills from the operator.

Water jet cutting: Using high-pressure water to cut materials is a dust-free and environmentally friendly process. Water jet cutting is suitable for cutting various types of granite without causing thermal damage, and is very suitable for cutting precious or fragile stones. However, water jet cutting has the lowest efficiency.

Final thoughts on the advancements in granite cutting technology and their impact on the industry.

Advanced cutting technology has brought many benefits to the processing of granite countertops. First, the improvement of cutting efficiency shortens the production cycle and reduces manufacturing costs. Second, the improvement of cutting accuracy makes the processing of granite countertops more refined, which can meet consumers' demand for high-end quality. Finally, the environmental advantages of the new cutting process cater to the concept of sustainable development and open up a broader space for the application of granite countertops.