Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-07-06

Within the stone industry, achieving intricate designs and precise cuts is crucial for countertops, sculptures, and various other applications. Computer Numerical Control (CNC) machines have become a cornerstone for stone working professionals, offering a blend of automation and precision unmatched by traditional methods.

1.Understanding CNC Technology

CNC technology empowers machines to function based on pre-programmed instructions. These instructions detail the movement of tools and materials, allowing for highly accurate and repeatable tasks. This computer-controlled approach ensures consistent quality and efficiency in production.

2.CNC Applications in Stone Cutting

The versatility of CNC machines extends to various stone materials. They offer significant advantages over traditional cutting methods for stone applications, including:

Precision Cutting: CNC machines guarantee highly accurate cuts, minimizing waste and ensuring a perfect fit for countertops, tiles, and other stonework.

Intricate Designs: Complex designs can be effortlessly translated into stone using CNC technology, enabling the creation of sculptures, signage, and other artistic elements with intricate details.

Automation and Efficiency: CNC machines automate the cutting process, reducing reliance on manual labor and improving production efficiency.

Material Versatility: A wide range of stone materials, from granite and marble to engineered stone, can be effectively cut using CNC machinery.

Improved production environment: Due to the characteristics of automation, CNC processing reduces the physical requirements of operators and improves the working environment.

In conclusion, CNC machines have become a vital tool within the stonework industry. Their ability to deliver precise cuts, handle intricate designs, and automate tasks makes them a powerful solution for modern stone fabrication.

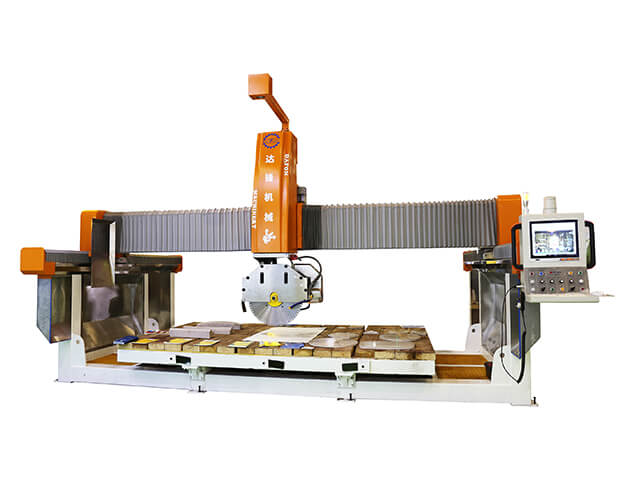

CNC Bridge Saw

CNC bridge saws are the most common type of CNC machine used for cutting stone. They are typically used for cutting countertops, slabs, and tiles. Bridge saws through a diamond saw blade to cut the stone, and they can be programmed to make very precise cuts.

There are several different types of CNC bridge saws, including:

3-axis bridge saws: These are the most basic type of bridge saw. They can only move the blade in three directions: up and down, left and right, and forward and back.It is usually for cutting straight line granite marble stone ect.

Based on the 3-axis bridge saw upgrade the processing technology, which allows them to make curved cuts,and make it more frequent, These saws can also tilt the blade, which allows them to make beveled cuts.it is more suitable for stone finishing, chamfering splicing cutting countertop slabs

Based on the 4 axis bridge cutter with additional milling cutter, which can digging cutting the hole for stone countertop, more functions than 4 axis bridge cutter

These are the most advanced type of bridge saw. They can move the blade in all five directions, which allows them to make very complex cuts,like milling, cutting ,drilling and engraving.

Water jet stone cutting machines use a high-pressure stream of water to cut the stone. The five-axis water jet can easily solve the problems of special-shaped stones, which not only reduces the time cost, but also improves the precision of the process. They are typically used for cutting very delicate or intricate designs, as they do not create any heat or dust.

The best type of CNC machine for you will depend on your specific needs and applications. If you need to make precise cuts in countertops, slabs, or tiles, then a 3-axis, 4-axis CNC bridge saw is a good option. If you need to cut delicate or intricate designs, then a 5-axis bridge saw or a water jet stone cutting machine is a better choice.

Here are some additional factors to consider when choosing a CNC machine: