Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-07-04

Stone chamfering and rounding are two common stone edge processing techniques, which are designed to improve the safety, aesthetics and touch of stone and are widely used in architectural decoration, home decoration and other fields. This article will deeply analyze the differences in processing technology and application scenarios between the two, and provide professional reference for stone processing and application.

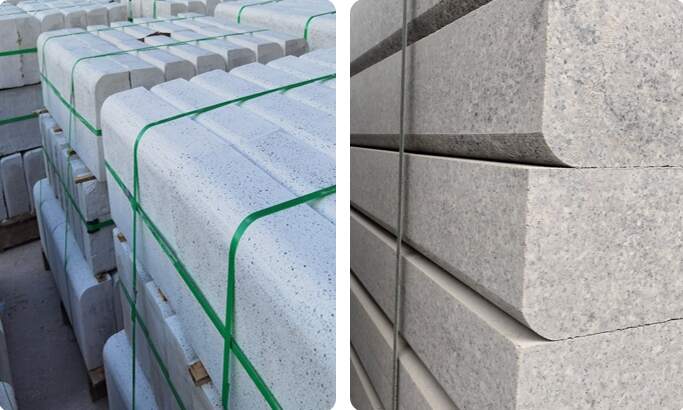

Stone chamfering

Stone chamfering is to round or bevel the edges of the stone to make the edges smooth and rounded. This treatment can increase the beauty of the stone while avoiding sharp edges and corners and improving safety. Stone chamfering is usually divided into two types: right-angle chamfering and rounded chamfering. Right-angle chamfering is suitable for situations where right-angle edges need to be maintained, such as steps, skirtings, etc.; rounded chamfering is suitable for situations where sharp edges need to be avoided, such as floors, walls, etc.

Stone rounding

Stone rounding is to trim the edges and corners of the stone to make them round. Unlike chamfering, the processing method of rounding is more complicated and requires the use of professional edge grinding machinery and equipment. During the rounding process, the edge of the stone will be gradually ground away to form a rounded arc. The size of the rounded corner can be adjusted as needed, usually measured by radius. Rounding can make the edges and corners of the stone softer and reduce the sharp feeling, while also increasing the touch and beauty of the stone.

Stone chamfering:

· Manual chamfering: Suitable for small-area stones or scenes with low processing accuracy requirements, usually operated with angle grinders or handheld grinding tools.

· Machine chamfering: Suitable for large-area stones or scenes with high processing accuracy requirements, usually processed with professional stone chamfering machines or CNC processing equipment.

Stone rounding:

· Manual rounding: Suitable for small-area stones or scenes with low processing effects requirements, usually operated with handheld grinding tools.

· Automatic rounding: Suitable for large-area stones or scenes with high processing effects requirements, usually processed with professional stone rounding machines or CNC edge grinding machines.

Stone chamfering

The key processing parameters of stone chamfering include chamfer angle and chamfer width. Chamfer angle refers to the angle formed by the bevel and the edge, and common angles are 45°, 60° and arc. Chamfer width refers to the width of the bevel or arc

Stone rounding

The key processing parameter of stone rounding is arc radius. Arc radius refers to the radius of curvature of the arc, and the size can be customized according to design requirements. In addition, surface finish is also an important parameter that affects the processing effect, and is usually expressed by roughness value.

The hardness and brittleness of the stone affect the choice of processing technology. For granite with higher hardness, a larger chamfer angle or arc radius can be used; for stone with greater brittleness, a smaller chamfer angle or arc radius should be used, and attention should be paid to controlling the grinding force to avoid stone breakage.

Stone chamfering and stone rounding have different uses. Stone chamfering is usually used for floors, countertops, stairs and other parts that need to be frequently touched. The chamfered stone edge is not only smoother, but also reduces the risk of people getting hurt. In addition, chamfering can make the transition between stone and other materials more natural and enhance the overall aesthetics.

Stone rounding is more used in decorative occasions. The rounded stone edges are softer, giving people a warm and comfortable feeling. This processing method is common in interior decoration, sculptures, building facades and other fields that need to emphasize the touch and beauty of stone. By rounding the corners, the edges of the stone can be better integrated with the surrounding environment and other materials, creating a more harmonious and unified effect.