Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-06-22

The strength of stone, that is, its ability to resist damage, is closely related to its thickness. The thinner the plate, the weaker its compressive strength, and the easier it is to break; conversely, the thicker the plate, the greater its compressive strength, and the less likely it is to break or break.

Selling thinner and thinner slabs has become a trend. In order to reduce the price of large slabs and improve competitiveness, merchants tend to sell thinner and thinner stone slabs. However, too thin stone thickness will bring the following series of disadvantages:

1. Easy to break: Natural stone itself has cracks, and the thinner the thickness, the easier it is to break and break.

2. Color re-seepage of cement and other adhesives: Thin stone will cause cement and other adhesives to re-seep to the surface of the stone through cracks and capillaries, affecting the appearance.

3. Poor bearing capacity: The thinner the stone thickness, the weaker the bearing capacity, and it is easy to break under heavy pressure. It is not suitable for places with large traffic or heavy vehicles passing by.

4. Weak impact resistance: The thinner the stone thickness, the weaker the impact resistance, and it is easy to be damaged by impact.

5. Easy to deform and warp: The thinner the stone thickness, the easier it is to deform and warp, especially in large-sized stone slabs with large aspect ratio.

6. Poor dimensional stability: The thinner the stone, the worse the dimensional stability, and it is more susceptible to dimensional changes due to factors such as temperature and humidity.

From the physical and chemical properties of the rock, marble strength, surface density, water absorption, and other physical and chemical indicators are behind the granite. Therefore, whether it is the exterior stone or interior stone, marble product thickness should be thicker than granite products to be safer and more reliable. As for the building decoration in which the thickness of stone decoration is better, should be analyzed on a case-by-case basis, and can not be generalized.

1.The thickness of exterior wall products and interior products should be treated differently

In the 1990s, the thickness of stone exterior wall granite and marble slabs was not less than 30mm. As the times progress, the thickness of stone exterior wall granite products has become 25mm, and some projects even have marble thickness of 25mm.

From a mechanical point of view, the thinning of the thickness of exterior wall products means that the wind load resistance, impact resistance, and bending resistance are all declining, which also means that buildings decorated with stone are full of various safety risks. As long as the conditions are met, the hidden safety risks may erupt at any time, leading to serious safety accidents.

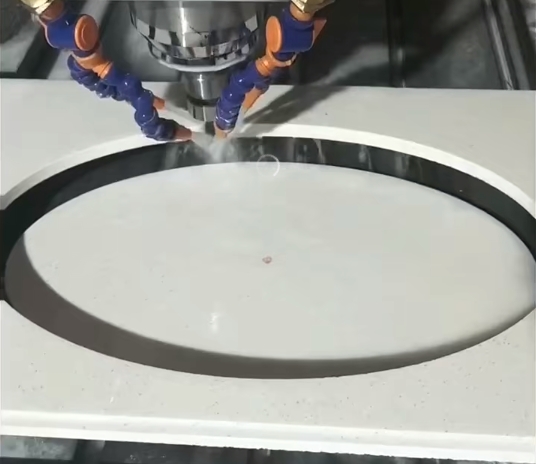

2.The thickness of countertop with holes and those without holes should be different

countertop are an important part of kitchens and bathrooms. Their thickness affects not only the aesthetics but also the safety. Generally speaking, the thicker the countertop, the stronger its load-bearing capacity and bending resistance, and the less likely it is to break.

countertop with holes: Since holes will reduce the strength of the countertop, the thickness of countertop with holes should be greater than that of countertop without holes. Generally speaking, the thickness of countertop with holes should not be less than 20 mm, while the thickness of marble countertop should not be less than 25 mm.

countertop without holes: The thickness of countertop without holes can be relatively thin, generally more than 15 mm. However, if the countertop needs to bear a large load or is often impacted, it is recommended to use a thicker countertop.

3.Thickness of stair tread products

The reason why stone-decorated stair treads crack and break at the front end is that the treads are too thin and lack strength. However, stone treads with a thickness of less than 20mm or even 15mm are commonly used in the market, and they are thickened by adding edges. This approach obviously cannot fundamentally solve the problem. Adding edges cannot effectively improve the overall strength of the treads, and the treads will still crack and break during long-term use.

In order to ensure the safety and durability of stair treads, it is recommended to use stone with a thickness of not less than 30mm for processing.

4.The thickness of floor products and wall products should be different

The difference in thickness between floor and wall stones is not arbitrary, but is set based on safety and functional considerations. As a material that bears the weight and friction of objects, floor stones need to have higher compression resistance and wear resistance, so the thickness should be at least 5 mm thicker than wall stones.

5.Different application places should have different thicknesses

Large public squares, railway stations, stadiums and other places have large traffic and heavy traffic, and even heavy vehicles pass through, which requires high bearing capacity of ground stone. Therefore, such places should use thicker (generally not less than 6cm) stone to ensure its durability.

Hotels, shopping malls, office buildings and other places have relatively small traffic and small traffic, and the bearing capacity requirements of ground stone are relatively low. Therefore, such places can choose thinner (generally 3-5cm) stone, which is both economical and beautiful.