Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-06-17

Stone surface treatment is to ensure the safety of the stone itself under the condition of its surface using different processing treatment.Let it show different material styles to meet various design needs.

According to the actual use, can be roughly divided into the following four categories:

1. Regular surface treatment: including polished surface, matte surface and so on.

2. Anti-slip surface treatment: including acid wash surface, flamed surface, cloth surface, water spray surface, lychee surface, Pineapple stone surface and so on.

3. Decorative surface treatment: including antique surface, grooved surface, mushroom surface, natural surface, sandblasted surface, pickled antique surface, etc.

4. Carving board and special surface treatment: as long as you can think of the surface texture can be realized, such as crocodile skin carving, waterline carving, etc.

1.polished surface

Polished surface refers to the use of a stone polishing machine will is a flat plate for rough grinding, fine grinding, fine grinding polishing, and processing of the finish. This surface is as bright as a mirror, with bright colors, few pores, and very small general stone luminosity that can be done 80, to 90 degrees, which is characterized by high luminosity, a strong reflection of light, and often can fully demonstrate the stone itself rich and colorful colors and natural texture!

2.Matte finish

Matte surface refers to the surface being flat, with resin abrasives and other less abrasive treatments on the surface. Its luminosity is lower than the polished surface, generally in the 30-60 or so after the matte treatment of the stone, often with a certain degree of luminosity, but the reflection of light is weaker, is a kind of flat and smooth surface, but the luminosity of the lower plate

1. Acid washing surface

Acid washing surface is through the use of strong acid corrosion of the stone surface to achieve visual effects, after treatment of stone, the surface will have smaller corrosion traces, more rustic than the polished surface looks more rustic, and the strong acid will not have an impact on the internal stone. This process is common in marble and limestone, non-slip performance is better, more used in restrooms, kitchens, road places, but also often used to soften the luster of granite

2. Fire surface

Fire surface refers to the use of acetylene, oxygen as a fuel or propane, oxygen as a fuel, or with liquefied petroleum gas and oxygen as a fuel to produce high-temperature flame on the surface of the stone processed into the rough surface finish due to the effect of the fire can be burned off the surface of the stone some of the impurities and low melting point of the ingredients, so as to form on the surface of the rough surface finish.

3. water washing surface

Fire washing surface is a heat treatment method using high temperature flame on the surface of the stone. In the flaming process, the crystal structure of the stone surface will be destroyed, forming a unique rough texture. Subsequently, the stone surface is sprayed or dipped in water so that the stone absorbs water and expands, resulting in a natural bumpy texture.

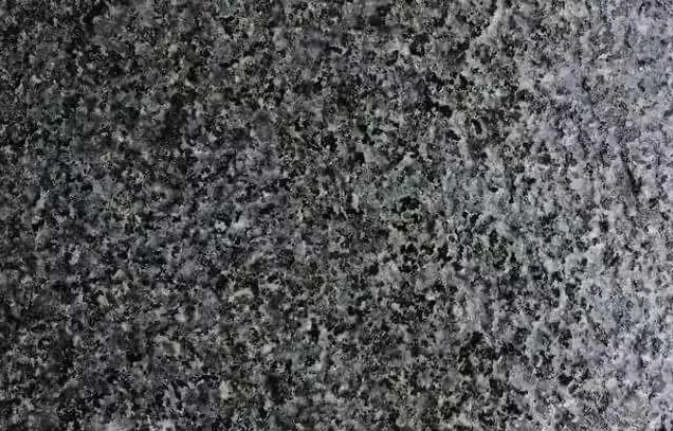

4. Litchi stone surface

Litchi surface: the use of an automatic bush hammer machine on the surface of the stone role, the formation of a rough texture similar to lychee rind, to increase the non-slip performance of the surface of the stone and aesthetics. Processing, the main use of abrasives of different particle sizes, shapes speed, and other factors, the stone surface grinding treatment.

5. Pineapple stone surface

Pineapple stone surface is the practice of processing the surface of the stone more uneven than the lychee surface, the sense of grain is more obvious. Its material texture is exactly the opposite of the wash surface, bumpy feeling is weaker, granularity is big.

1. antique surface

The antique surface using a slab flaming machine will stone after flaming, and then the Abrasive Brushes brush 3-6 times, that the antique surface. The antique surface has the concave and convex feeling of the flamed surface, but also smooth and will not be harsh to the touch, which is a very good surface treatment method.

2.groove surface

Pull groove surface, also known as "pull groove" or "pull wire", which is the use of a slab surface line cutting machine in the stone surface to open a certain depth and width of the groove, usually pulls a straight line groove, there is a two-way slot (5mm × 5mm) and one-way slot (5mm × 5mm) and one-way slot (5mm × 5mm). 5mm × 5mm) and unidirectional groove points

3.Mushroom stone surface

Mushroom surface refers to the stone surface with hammers to shape the plate-like an undulating mountain shape this processing method of stone thickness has certain requirements generally at least 3 cm thick at the bottom, the raised part can be based on actual requirements in more than two centimeters this processing method is common in the economic fence.

4.natural surface

Natural surface commonly known as natural fractured surface, or cracked surface, is a stone splitting machine with stone splitting machine a stone from the middle of the natural split, split without any treatment, this stone surface is extremely rugged, and extremely uneven, in the light of the irradiation, appears to be particularly tense, the natural surface of the marble should also be taken into account the weight of the stone, thickness, specifications and the installation process, applicable to the natural style, rugged style of the wall, the natural style of the wall, the natural style of the wall, the natural style of the wall, the natural style of the wall, the natural style of the wall, the natural style of the wall. In the natural style, rough style space

5.sandblasted surface

Sandblasting is a kind of high-pressure air or water impact on the surface of the stone processing technology so that its surface presents a similar effect to frosted glass. This process not only gives the stone a unique visual effect, but also makes it have excellent anti-slip properties, so in the field of architectural decoration, landscaping, interior furnishings, and other areas have been widely used!

This processing method combines the two advantages of anti-slip and aesthetic, so the application range is very wide. It is not only suitable for the processing of natural stone slabs such as thin slabs and specification slabs, but also the processing of shaped stones such as lines, columns, railings, steps, and corners. In addition, it is also widely used in the field of stone carving. Hotels, conference rooms, museums, corridors, and other places can see the application of this processing technology.

Carved stone slabs expand the artistic boundaries of stone finishes, enabling an almost limitless range of textural effects. Carved marble slabs take this trait to the extreme, with beautiful decorative effects that are breathtaking to behold.