Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-06-13

The marble surface we commonly see is smooth and beautiful. This is not naturally formed, but has undergone multiple processing steps. Among them, marble polishing is particularly critical and is an indispensable step in stone care. So, how should marble be polished? Let's discuss it in detail below.

In the marble slabs processing treatment, polishing can be said to be a crucial step, which gives the marble slabs charming luster and texture. Nowadays, with the advancement of science and technology, polishing technology is becoming more and more mature, a variety of polishing equipment is emerging, adding more possibilities for the beauty of marble slabs

Marble slabs polishing is an indispensable step in stone processing, which can make the surface of the stone smooth and bright, increase the beauty and service life of the stone. Marble slabs polishing process mainly includes rough grinding, fine grinding, precise grinding, and polishing four stages.

1.Rough grinding

Rough grinding is the foundation of stone polishing, the purpose is to remove the unevenness of the stone surface. Rough grinding can be used 50 #, 150 #, 300 #, and 500 # gold steel stone resin hard grinding block, Rough grinding should account for 45% of the overall grinding time.

2.Fine grinding

Fine grinding is the stage to further improve the surface flatness and glossiness of the stone slabs. Fine grinding can use 800#, 1000#, 2000# diamond resin soft water grinding discs, and fine grinding should account for 35% of the overall grinding time. After fine grinding to 2000#, the glossiness of the stone surface can reach 50 degrees.

3.Precise Grinding

Fine grinding is the last step in the stone polishing process. The purpose is to maximize the surface gloss of the marble slabs. Fine grinding should account for 20% of the overall grinding time. After fine grinding, the surface gloss of the stone will be significantly improved and lay a good foundation for polishing.

4. Polishing

Polishing is the key step to make the stone surface as bright as a mirror. Polishing can be done using an marble slab line polishing machine. After polishing, the glossiness of the marble surface can reach more than 90-100 degrees.

Stone slab grinding and polishing equipment is an indispensable equipment in the stone processing industry, mainly used for slabs, and slats for grinding and polishing, to obtain a flat and smooth surface. Currently on the market common slab grinding and polishing equipment are mainly the following: automatic marble slab line polishing machine, single arm manual polishing machine, and multi-head bridge polishing machine.

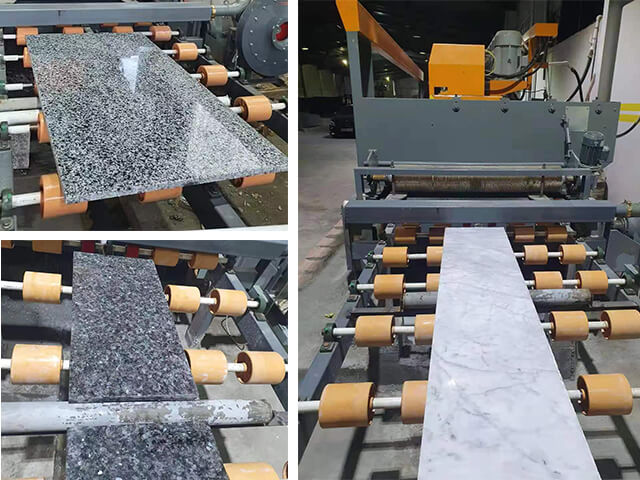

1. Automatic marble slab line polishing machine

The fully automatic slab line polishing machine is the ideal, most efficient, and best-quality continuous polishing line for polishing large stone slabs and strips. fully automatic continuous polishing line with a fully automatic plate turning machine, plate transition conveyor, plate transition device, and fully automatic plate unloading machine to form a polishing line, suitable for large-scale polishing enterprises.

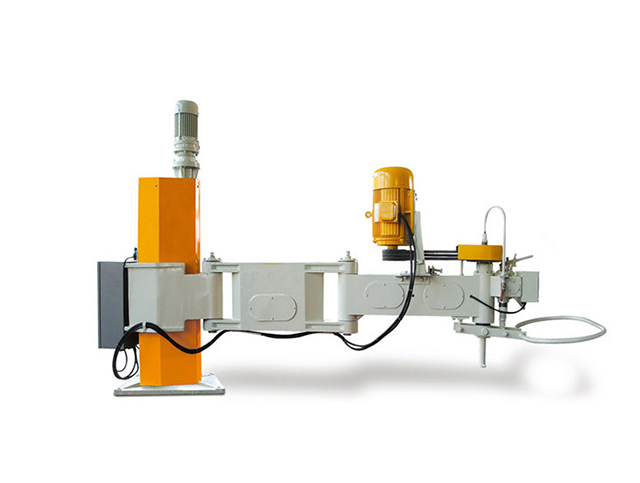

2. Single arm manual polishing machine

single arm manual polishing machine is a simple structure, flexible operation, occupies a small site grinding and polishing equipment, not only can grind and polish the flat slab, can also be ground and polished to see the edge of the stone, so the use of the stone industry is still quite extensive, suitable for small stone processing plant or family use.

3. Multi-head bridge polishing machine

The multi-head bridge polishing machine is only suitable for grinding and polishing slats below 900mm due to the influence of running width, not suitable for grinding and polishing large slabs. However, the multi-head bridge polishing machine can be more than one head grinding and polishing at the same time, coupled with easy-to-operate, inexpensive equipment, grinding and polishing slats of high productivity, welcomed by small and medium-sized stone enterprises.

With its natural elegant texture and luster, Marble has become the darling of home decoration. However, it must undergo a key process to fully display its ultimate beauty.

Polishing gives marble the magic of brilliance. Fine grinding and polishing make the marble surface as smooth as a mirror, with a gloss of 90-100 degrees, and a delicate and warm texture, making it more wear-resistant, easy to clean, and extending its service life.

Polishing is not only an improvement in appearance, but also a manifestation of its inner quality. The dense surface is not easy to penetrate stains, making it easier to clean; the smooth surface also reduces the growth of bacteria, which is more conducive to home health.

Marble polishing achieves a gorgeous luster and highlights the style of your home. Choose polished marble to add a touch of luxury and elegance to your home.