Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2024-01-16

Whether you want to invest in a new Stone Polisher, choose an efficient working way, learn about parts or know the working principle, you should read this guide.

It has all information you are looking for about stone polisher

A polishing machine is a mechanical device used to grind and polish stone surfaces. It can be replaced with different types of abrasives to achieve various processing stages from rough grinding to polishing.

stone polisher can be used to process various types of stone such as marble, granite, and limestone, and are suitable for repairing, renovating, and maintaining stone surfaces.

Despite having a common form, you will still find Stone Polisher in many types, shapes, and functions.

These Stone Polishers have three broad categories, You will later notice from our broad analysis that they have some differences.

That said, let us now go through the different types of Stone Polisher:

1. Classification by structural form

Manual polishing machine: It usually has a rotating grinding disc, and the operator needs to hold the machine by hand to perform polishing operations. It is an electric tool that is easy to operate and suitable for polishing stones in small areas or detailed parts. Mainly used for polishing local stones, easy to operate and highly flexible

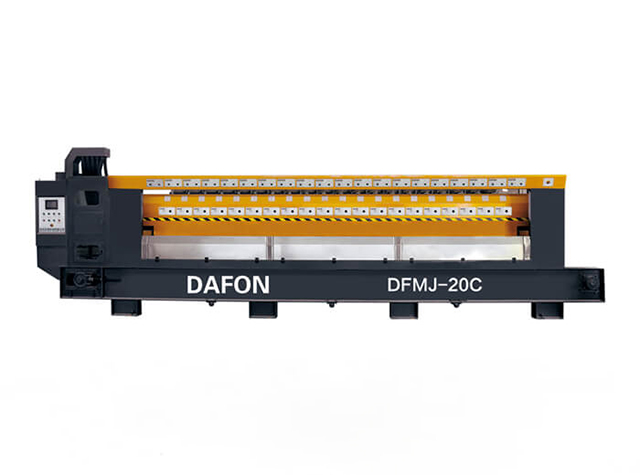

Automatic polishing machine: It is a stone polishing equipment with a high degree of automation. It adopts a continuous operation method to automatically control the stone during the polishing process, thereby improving production efficiency and polishing quality. Mainly used for large-area, continuous stone polishing, high work efficiency, but expensive, stable polishing quality and other advantages

2.Classified by place of use

Surface polishing machine: It is a machine specially used to polish the surface of flat stone materials, such as marble, granite, limestone, etc. It usually needs to be used with abrasives and polishing fluids to achieve the ideal polishing effect. Mainly used for polishing flat stone surfaces, such as floors, walls, countertops, etc.

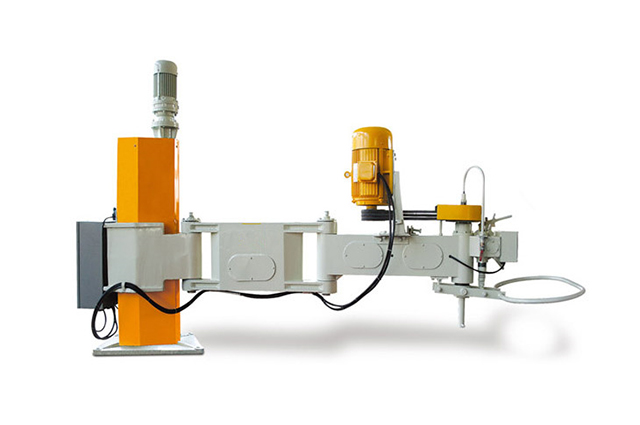

Special-shaped line polishing machine: a piece of mechanical equipment specially used for polishing various special-shaped stone lines, such as stairs, handrails, window sills, etc. This kind of polishing machine has the characteristics of high efficiency, high quality, and easy operation, and can meet the needs of different customers.

Edge polishing machine :it is a mechanical equipment used for polishing the edges of stone materials, such as countertops and boards. This kind of polishing machine has the characteristics of high efficiency, high quality, and easy operation, and can meet the needs of different customers.

3.Classification by Processing

Wet polisher: It is a polishing equipment that uses water or polishing fluid as a cooling and lubricating medium. Mainly used for preliminary polishing of stone, using water as the grinding medium, which can effectively reduce the temperature of the stone surface and prevent stone cracking

Dry polishing machine: Dry polishing machine mainly relies on air for cooling and lubrication. It is mainly used for fine polishing of stone. Using dry abrasives can improve polishing efficiency, but the surface temperature of the stone is high and it is easy to crack.

These Stone Polisher can offer you so many benefits when you apply them to your stone process. Consider the following as some of these advantages that you are bound to enjoy:

High efficiency:

Stone polisher adopts automation and mechanization of processing, which can greatly improve polishing efficiency, shorten processing time, and improve productivity.

High quality:

stone polisher machine can ensure the consistency of polishing quality, so that the polished stone surface is smooth, high brightness, improving the beauty and value of the stone.

Reduce labor intensity:

It can reduce the labor intensity of workers, and reduce labor costs while reducing the risk of work-related accidents.

Cost savings:

Can accurately control the polishing process, reduce stone loss, and reduce processing costs.

Wide application:

stone polish machine is suitable for various types of stone, such as marble, granite, etc., and can meet the needs of different customers.

Easy to operate:

Easy to operate, after simple training, workers can quickly master the operation method, and improve production efficiency.

Enhance corporate image:

The use of advanced stone polishing machines can enhance the production capacity and technical level of enterprises, and enhance the competitiveness of enterprises in the market.

The main operation of the Stone Polisher to polish stone is to try to obtain the maximum polishing rate and to use "dry polishing and wet polisher" to achieve the polishing effect so that the surface of the product will have strong reflected light, which is commonly referred to as gloss.

The principle of polishing is mainly reflected in the principle of particle grinding and physical and chemical principles. Particle grinding: When the abrasive particles change from coarse grinding to fine grinding and polishing, the traces of grinding by the abrasive on the stone surface will not be visible to the naked eye, and the surface will appear smooth and smooth. Smooth and delicate, when the depth reaches a certain level, the surface of the stone will appear mirror-like luster. There are two polishing processes based on physical and chemical principles, namely "dry polishing and wet polishing". Dry polishing means that the temperature of the stone surface increases to evaporate water, increasing the concentration of polishing abrasives, thereby achieving a strengthening effect. The glossiness of the product is improved. Don't bother polishing the stone. After the product is hot, add an irregular amount of water to the surface of the plate to cool down. This is wet polishing.

Machine body:

Support the structure of the entire equipment to ensure stable operation of the equipment.

Transmission system:

Including motors, reducers, etc., used to drive the polishing wheel to rotate.

Control System:

Including switches, adjustment knobs, sensors, etc., used to control the operation of equipment and adjust parameters to achieve automated control.

Hydraulic or pneumatic system:

Used to provide water or polishing fluid to cool and lubricate during the polishing process. Some equipment may use a pneumatic system to provide compressed air for cooling and lubrication.

Conveyor system:

It is used to transport stone workpieces to be polished, usually in the form of belt conveyors, chain conveyors, etc.

Grouped equipment:

Depending on production needs, it may also include auxiliary equipment such as automatic loading machines, automatic unloading machines, cleaning equipment, and drying equipment to achieve automated production of stone processing.

Marble and granite are two common stones with different physical properties. Marble has a soft texture and is easy to polish, but has poor wear resistance; granite has a hard texture and has good wear resistance, but is more difficult to polish. There is a big difference between a marble polisher and a granite polisher

Granite Slabs

To polish granite slabs, there are two types of polishing machines available on the market: resin automatic line polishing machines and Fickert head polishing machines.

The resin automatic line polishing machines are suitable for slabs with a width of less than 1400mm, but some customers will choose to use automatic grinding with resin grinding heads to polish slabs with a width of 1500-1600mm.

The Fickert head polishing machine is suitable for large granite slabs with a width of more than 1400mm.

Fickert head polisher and resin automatic line polishing machines are both polishing machines used for granite slabs, but there are certain differences between the two in terms of polishing quality, efficiency, cost, etc.

The polishing quality of the Fickert head polishing machines is higher and the surface is brighter, but the overall cost is also higher. This is because the motor of the Fickert head polisher is more powerful and the price of the abrasive is higher.

The speed of polishing is closely related to the flatness of the slab. The smoother the surface, the faster it can be polished. This is because the surface of a large plate with high flatness has less unevenness and consumes less abrasive, so the polishing speed is faster.

Marble Slabs

A frankfurt head marble polishing machine is a piece of equipment used for stone polishing. frankfurt abrasives are mainly used for polishing marble, which can effectively remove the roughness of the marble surface and make it smoother. The motor drives the grinding head to rotate, and the Frankfurt abrasives on the grinding head contact the surface of the marble slab to grind it. Make its marble surface brighter