Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2023-11-27

Marble has been used in construction and sculpture for thousands of years, and the need for efficient tools to shape and cut this beautiful stone has been a constant challenge. The development of marble cutters has greatly impacted the way marble is processed, providing faster, more precise, and safer methods for cutting this delicate material.

Early methods of cutting marble involved manual chiseling and hammering, which required tremendous skill and effort. This limited the scale and intricacy of the designs that could be achieved and was time-consuming. As demand for marble grew, there was a clear need for more efficient cutting methods.

The invention of the first marble cutting machine revolutionized the industry. In the 19th century, steam-powered saws were introduced, enabling large blocks of marble to be cut with precision and speed. This innovation transformed the way marble was processed and opened up new possibilities for architectural and artistic applications.

With the advent of electricity, marble cutting machines became more accessible and versatile. Electric-powered marble cutters allowed for greater maneuverability and control, making it easier to create intricate designs and shapes. These tools also significantly reduced the physical strain on workers, leading to increased productivity and safety.

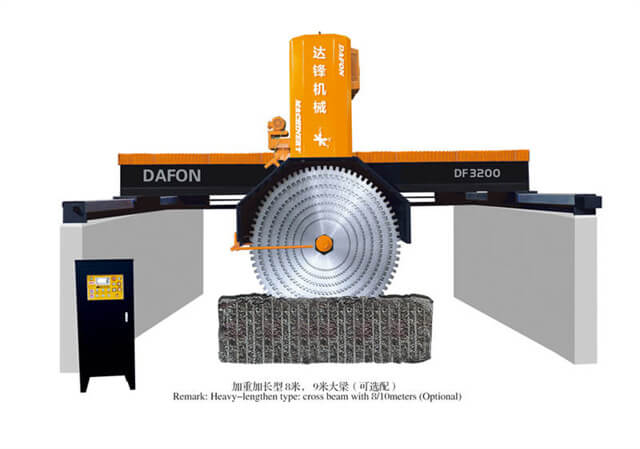

The use of diamond blades in marble cutters marked another significant advancement in the industry. Diamond's hardness and durability made it an ideal material for cutting through the tough composition of marble. This innovation resulted in cleaner cuts, reduced waste, and extended the lifespan of cutting blades, ultimately leading to cost savings for producers.

In recent decades, computerized control systems have been integrated into marble cutting machines, allowing for unprecedented levels of precision and customization. These systems enable complex patterns and designs to be executed with minimal margin for error, meeting the demands of modern architecture and design.

As technology has advanced, so have the safety features of marble cutters. Automatic shutoff mechanisms, blade guards, and ergonomic designs have made these machines much safer to operate, reducing the risk of accidents and injuries in the workplace.

Modern marble cutters are designed with environmental impact in mind. Efforts have been made to reduce dust and noise pollution, as well as to optimize energy efficiency. This reflects the industry's commitment to sustainable and responsible production practices.

The development of marble cutters has been a story of continuous innovation, from manual tools to computerized precision machines. These advancements have not only transformed the way marble is processed but have also improved efficiency, safety, and environmental sustainability within the industry. As technology continues to evolve, we can expect further refinements and improvements in the field of marble cutting.

```