Author:Dafon Kerbstone Machine FROM:Stone Machine Manufacturer TIME:2023-09-14

Introduction:

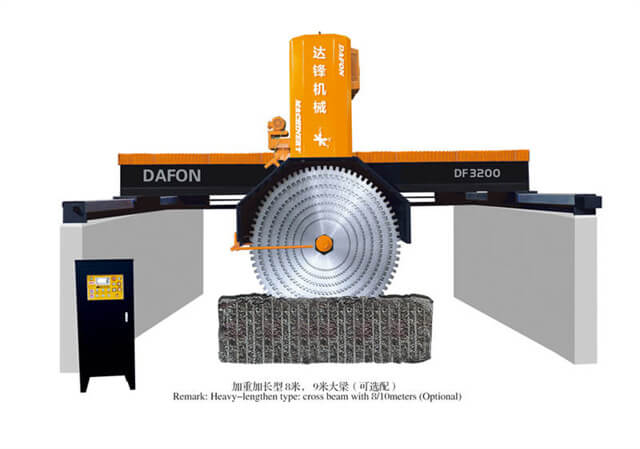

Essential Maintenance for Stone Cutting Machine Supplier

Maintaining a clean and lubricated stone cutting machine is crucial for its optimal performance and longevity. Regularly clean the machine to remove dirt, dust, and debris that can accumulate during the cutting process. Use a soft cloth or brush to gently wipe down the surfaces, paying special attention to the cutting blades, guides, and motor. Additionally, lubricate the moving parts and bearings with recommended oils or lubricants to ensure smooth operation.

The cutting blades of a stone cutting machine are subjected to significant wear and tear during operation. Inspect the blades regularly for signs of damage, such as chipping or dullness. Damaged blades should be replaced promptly to avoid compromising the quality of cuts and risking machine malfunction. Additionally, ensure that the blades are properly aligned and tightened to prevent vibrations and uneven cutting.

The electrical system of a stone cutting machine plays a vital role in its functionality. It is essential to regularly inspect and maintain the electrical components, including wires, connectors, switches, and control panels. Check for loose connections or signs of wear that could lead to electrical malfunctions or hazards. If any issues are found, contact a professional technician for repair or replacement.

Conclusion:

In conclusion, regular maintenance is key to ensuring the optimal performance and longevity of stone cutting machines. By following the essential maintenance steps mentioned above, a stone cutting machine supplier can provide reliable and efficient equipment to their customers. Proper cleaning, lubrication, blade inspection and replacement, and electrical system maintenance will contribute to smooth operation and minimize downtime. Remember, a well-maintained machine not only enhances productivity but also reflects the commitment to quality and customer satisfaction.