Regular Cleaning. Lubrication and Inspection. Calibration and Alignment....

1. Cleaning and Lubrication. 2. Blade Maintenance. 3. Electrical and Mechanical Components....

1. Regular Cleaning and Inspection. 2. Lubrication and Calibration. 3. Safety Measures and Operator Training....

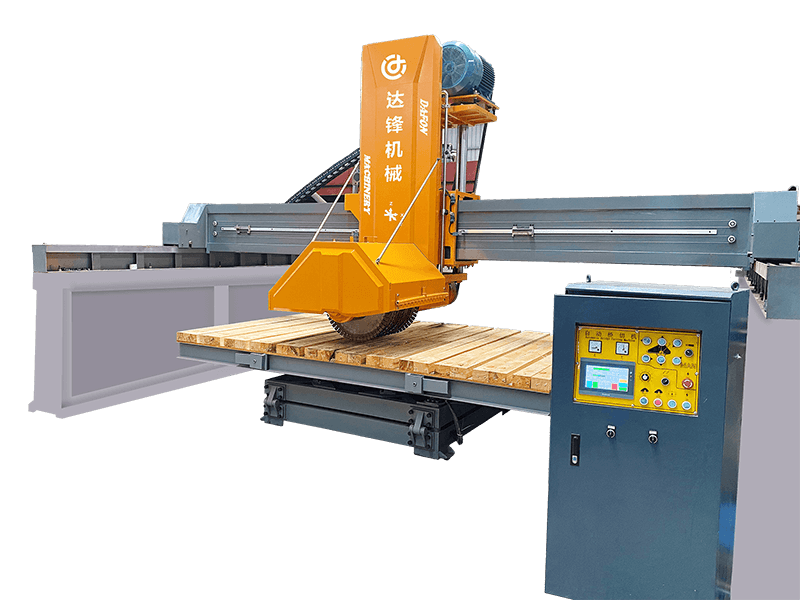

The stone cutting bridge saw was developed on the basis of hand-operated cutters and hydraulic cutters and is mainly used for cutting granite and marble slabs. 1.Advantages of the bridge saw cutting machine The stone cutting bridge ...

Introdution: This bridge cutter is improved and upgraded based on an infrared trimming machine, it adopts PLC to control multiple saw blades cutting at the same time, and it can hang u...

Introduction: 5 Axis w ater Jet cutting m achine consists of four parts: a cutting platform, a CNC operating system, a high-pressure system, and an automatic water jet sand feeding...

Introduction: A tile cutting machine is a common construction tool, mainly used for cutting tiles, marble, granite, and other hard materials. It adopts advanced electric power technolo...

A granite stone polishing machine is a specialized equipment used for polishing and buffing granite stones to achieve a smooth and glossy surface finish. There are several types of gra...

Marble floor stone grinding machine is a device used for polishing and smoothing marble floors. The machine uses a rotating diamond abrasive disc to grind and polish the surface of ...

Create an elegant, textured, and moisture-proof bathing space to enhance the use experience....