Introduction of Automatic Stone Floor Grinder An Automatic Stone Floor Grinder is a cutting-edge machine designed for grinding and polishing stone floors. It is widely used in various industries such ...

Introduction Features Technical Data Application...

Introduction Edge cutting machine is suitable for trimming and shaping imported rough materials and irregular stones. Users can choose ordinary workbench or electric rotary workbench. Ordinary work...

Stone edge cutting machines are advanced tools used in the stone industry for precision cutting and shaping of natural and artificial stone materials. They have revolutionized the process of stone fa...

This assembly line has replaced the previous curbstone mainly relying on artificial chamfering and polishing, which completely solved the situation of high labor intensity, low efficiency, and high co...

1. Bridge Saw Machine: It is a large, heavy-duty machine that can handle enormous stones. 2. Wire Saw Machine: This machine uses diamond-infused wire to cut through large blocks of stones. 3. Waterj...

Introduction to Granite Edge Cutting Machine If you are looking for a high-performance machine for cutting granite edges, then the Granite Edge Cutting Machineis an excellent option. This machine is...

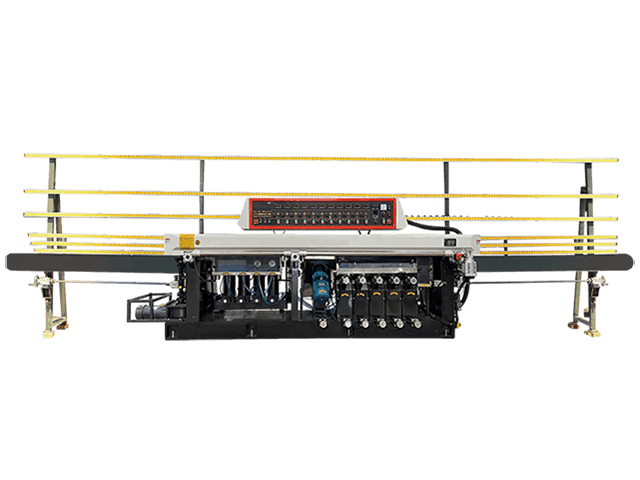

Stone edge grinding machine uses CNC, configuration touch screen, configuration wireless remote control, configuration worm buckle joint, the first six motors can be 45 degrees - 90 de...

The introduction of stone profiling machine Stone profiling machines come in different sizes and configurations, and their features depend on the specific tasks they are designed to ac...

Kerb stone cutting machine features: Note:if single DF1200-12 is required, roller on worktable is no need Kerb stone cutting machine advantages: 1. No foundation needed, easy installatio...

一.What is block cutting machine? A block cutting machine is an industrial tool designed to cut large blocks of stone into smaller, desired shapes and sizes. This process is crucial i...

Advanced Selection Tips for Heavy Duty Stone Cutting Machine Introduction In the field of stone cutting, heavy duty stone cutting machines play a crucial role in improving efficie...