Price:

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Application: Depends on head quantity

Weight: Art & Craft, Stone Industry

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

The granite line polish machine is an advanced equipment that combines high automation and high polishing efficiency. It is equipped with an advanced PLC control system and a human-machine interface, making the operation simple and easy to understand, suitable for all types of operators. Thanks to its continuous processing method, this grinder can maintain efficient and stable performance in large-scale production. In addition, the granite line polish machine has a low abrasive cost, which helps companies control production costs while maintaining high-quality polishing effects. The equipment is also very convenient to maintain, ensuring long-term stable operation, especially suitable for production environments that require large-scale, low-cost stone polishing.

Machine Parts

Specification

| Name | Unit | DFB-8 | DFB-12 | DFB-16 | DFB-20 | DFB-24 |

| Number of heads | pcs | 8 | 12 | 16 | 20 | 24 |

| Grinding polishing disks dia | mm | 200 | 200 | 200 | 200 | 200 |

| Max.width size | mm | 1250 customized | ||||

| Beam swing speed | m/mim | 3-35 | ||||

| Main motor power | kw | 6*7.5kw+2*9kw | 9*7.5kw+3*9kw | 12*7.5+4*9kw | 16*7.5kw+4*9kw | 19*7.5kw+5*9kw |

| Beam motor power | kw |

4 |

2*3kw |

|||

| Belt feeding speed | m/mim |

0.5-4 |

||||

| Belt motor power | kw |

2.2 |

3 |

4 | ||

| Total power | kw |

76.7 |

100.7 |

135 |

165 |

199.5 |

| Air pressure | mpa |

≧0.7 |

||||

| Water pressure | mpa |

0.1-0.15 |

||||

| Water consumption | L/min |

≧15 |

≧20 |

≧25 |

||

| Overall dimensions(L*W*H) | mm | 5560*2300*2300 | 6340*2350*2200 | 7460*2350*2200 | 8580*2350*2200 | 9700*2350*2200 |

Finished Products

Features

Granite line polish machine is a piece of equipment specially used for grinding and polishing the surface of hard stone materials such as granite. It combines the advantages of resin grinding heads and automatic control technology, and has the following salient features:

1. High processing efficiency

Continuous processing mode: Granite slabs can continuously enter and exit the mill, realizing automated assembly line operations, which greatly improves processing efficiency.

Multi-head grinding and polishing: Some models of resin mills are equipped with a multi-head grinding and polishing system, which can grind and polish multiple surfaces at the same time, further increasing the processing speed.

2. Excellent grinding and polishing quality

High-precision grinding head: Using high-quality resin grinding head, combined with a precise pressure control system, to ensure that the granite surface has high finish, good flatness, and a mirror effect.

Adjustable grinding and polishing parameters: Through the PLC control system, grinding and polishing pressure, speed, feed and other parameters can be accurately adjusted to adapt to different granite varieties and process requirements.

3. Easy to operate

Automated control: The equipment is equipped with a PLC programmable control system. The operator only needs to set the processing parameters to achieve automatic grinding and polishing without excessive manual intervention.

Human-computer interaction interface: Friendly operation interface makes equipment operation more intuitive and convenient, reducing the technical requirements for operators.

4. Strong adaptability

Wide scope of application: It can be used for grinding and polishing granite slabs of various specifications and thicknesses to meet the needs of different customers.

Easy replacement of abrasives: The resin grinding head is easy to replace, and abrasives of different particle sizes can be replaced according to different processing needs.

5. Stable and reliable

Solid structure: The equipment is made of high-quality materials, has a solid structure, high stability, and can work continuously for a long time.

Low maintenance cost: The equipment failure rate is low and the maintenance cost is low.

6. Environmental protection and energy saving

Water cooling system: Some models are equipped with a water cooling system, which can effectively reduce the operating temperature of the equipment, extend the service life of the grinding head, and reduce dust pollution.

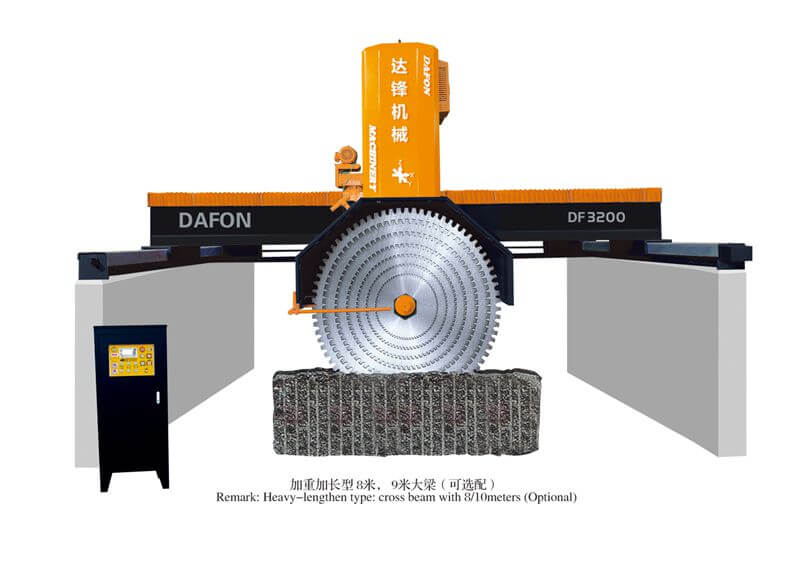

The block cutting machine left and right knife using frequency converter control, according to the quality of the stone material to adjust the speed, up and down lift using hydraulic lift (c...

A granite edge chamfering machine is a tool used to shape and polish the edges of granite slabs, countertops, and other surfaces. This machine uses diamond-coated grinding wheels to create a...

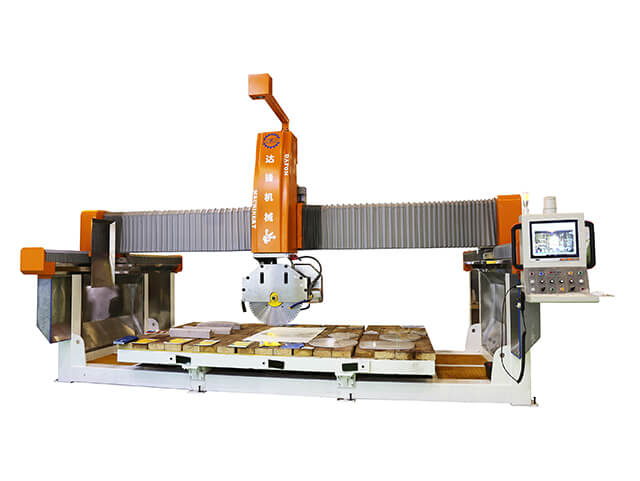

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse belly edge, ...

The bridge saw machine adopt cast iron on the main part of machine body ensure stability while cutting The cutting speed is controlled by inverter to achieve stepless adjustment, the head mo...

Introduction 4+1 Axis Bridge Cutter is based on the 4axis bridge cutter machine and adds an engraving head that is suitable for drilling or cutting granite, marble, and quartz stone counte...