The Advantage of Automatic Stone Cutting Machine 1.Segments saving: machine use multi-blade cut at the same time, every down cut is about 3-5mm(depends on stone and segment), which save se...

Natural stone cutting machines are widely used in various industries for processing and shaping stones. However, like any other machinery, these machines require regular maintenance to ensure their e...

Introduce the classification of laser rock cutting machineand engraving machine. With the development of modern machinery processing industry, the quality and accuracy of cutting requirements are ...

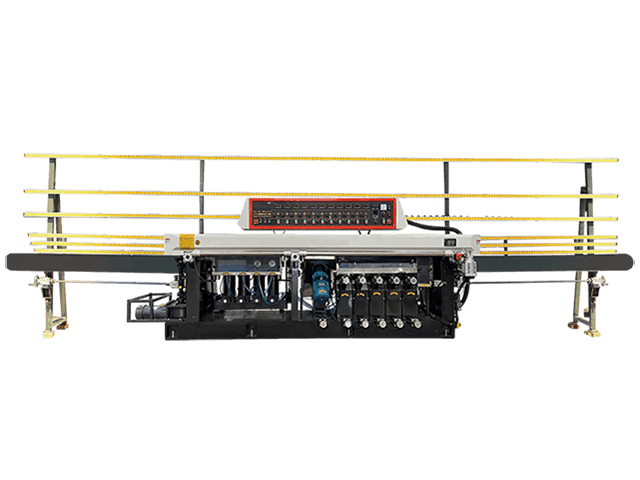

Stone edge grinding machine uses CNC, configuration touch screen, configuration wireless remote control, configuration worm buckle joint, the first six motors can be 45 degrees - 90 de...

The Introduction of stone splitting machine A stone splitting machine is a tool used to split or break stones into smaller pieces. It is commonly used in the construction industry t...

The introduction of stone profiling machine Stone profiling machines come in different sizes and configurations, and their features depend on the specific tasks they are designed to ac...

Introduction In the world of stone processing, efficiency and precision are paramount. Whether it’s for creating tombstones, flooring, or cladding, stone slabs need to be cut with u...

The Background of Stone Carving Machine Production Shaped stone shape is complex, both plane curve and three-dimensional space curve, the space surface constituted is also a variety o...