Price:

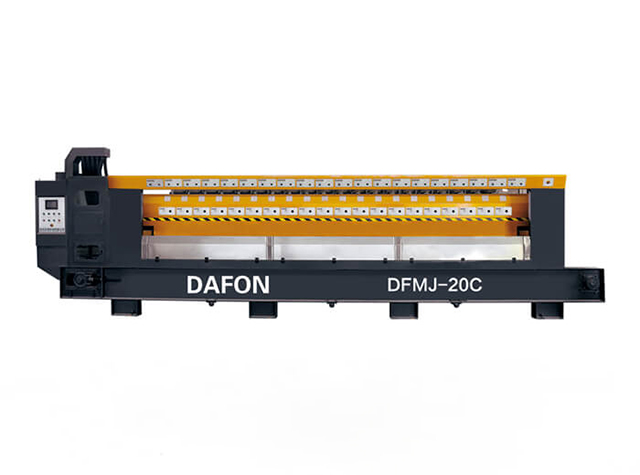

Brand Name: DAFON

Certification: CE, ISO

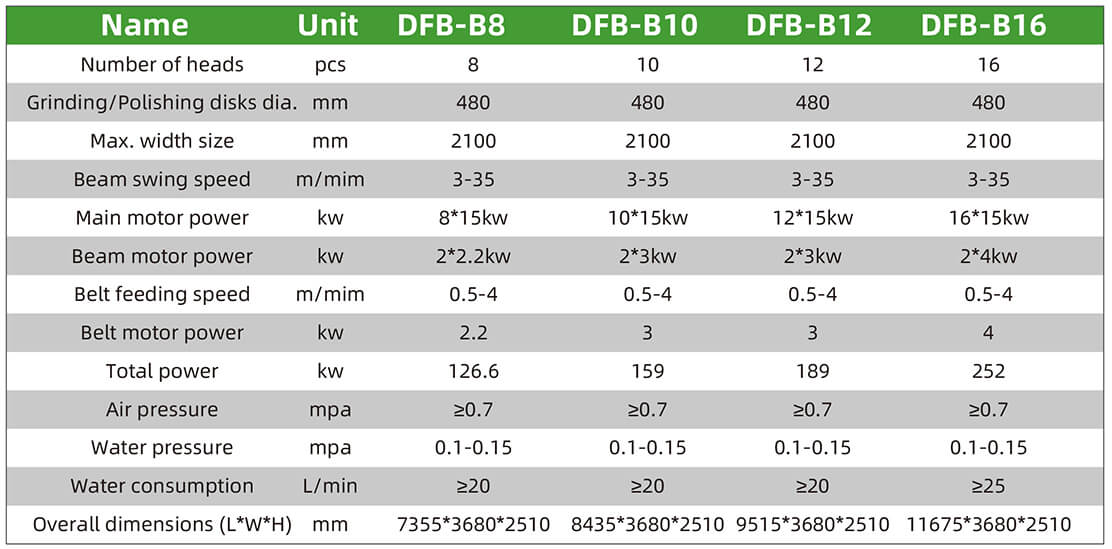

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Weight: Depends on head quantity

Application: stone/marble/granite

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

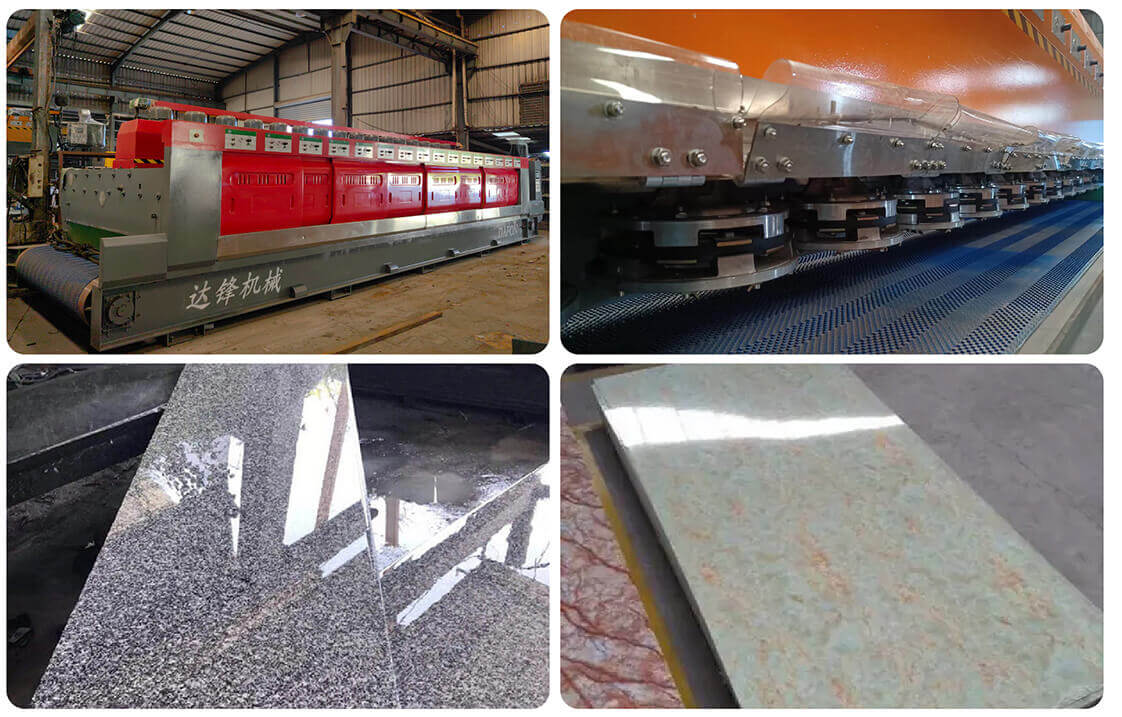

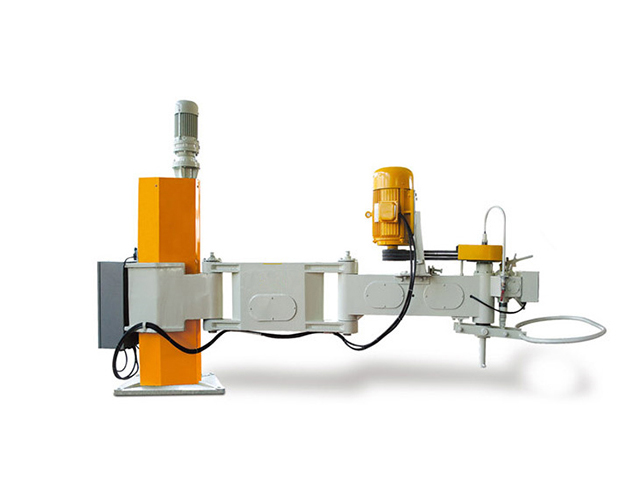

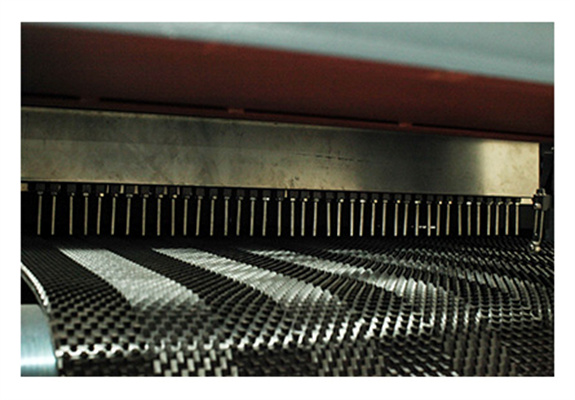

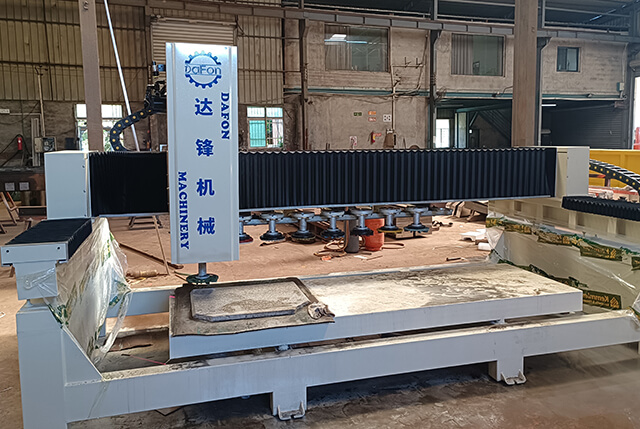

Granite stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodging function and shape memory function. allocation the abrasive consumption equip. which has high automation operation and low labor the strength.

Allocation the flexibility Resin polishing heads. Prominent improvement on the polishing efficiency and polishing quality and greatly reduced abrasive consumption.

FAQ:

S tone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dod...

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu o...

Allocation the flexibility Resin polishing heads. Prominent improvement on the polishing efficiency and polishing quality and greatly reduced abrasive consumption. Marble stone po...

Stone polishing machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodgi...

Stone machine is closely related to tools and we sell machines as well as giving advice to customers on how to buy diamond tools....

We offer a six-month warranty on Fickert Head Polishing Machine Line for Granite Marble....

We are able to provide stone machine solutions to our customers in a timely and efficient manner....

I've used this stone polisher machine for several months, and the results have been outstanding. It can automatic to change the polisher, so conveniently2024-07-15

Improve production efficiency immediately and the automatic change heads function is very confinement2024-07-18