Price:

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

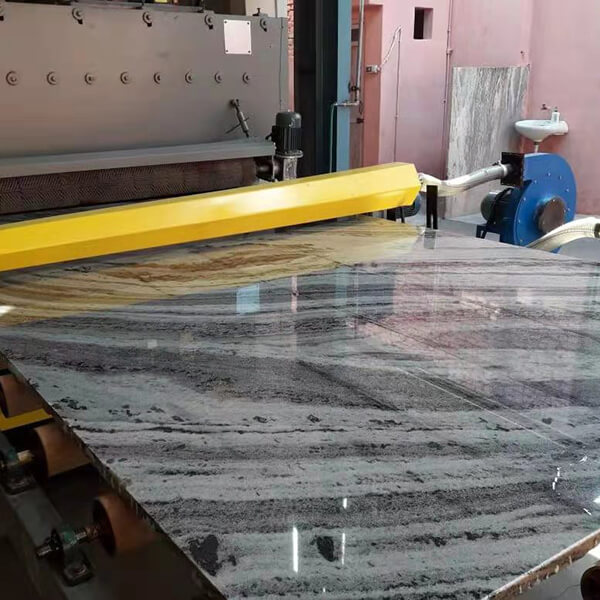

Application: Surface polishing granite

Weight: Depends on head quantity

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

1. Product Introduction :

Stone polisher machine is suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control. Establish Auto-dodging function and shape memory function. allocation the abrasive consumption equip. which has high automation operation and low labor the strength.

Allocation the flexibility Resin polishing heads. Prominent improvement on the polishing efficiency and polishing quality and greatly reduced abrasive consumption.

Granite polisher machine using the most advanced high quality construction , rational structure. high stability and efficiency and energy saving operation. The power movement of polishing heads using the spread-allied set, to improve slab flatness , reduce movement consumption and enhanced the longer working life. We can do the machines according to the client's requirements, like the number of heads, processing width and length.

2. Technique Description :

I. Suitable for the surface polishing granite/marble

II. Using PLC intelligent control system and through the LCD touch screen human-computer dialogue, to achieve intelligent control.

III. A grinding head automatic collision avoidance and shape memory function, and is configured to abrasive wear alarm device, the machine has high automation degree, low labor intensity.

IV. Allocation of special granite grinding head/marble elastic grinding, polishing and polishing quality, and greatly reduced abrasive consumption.

V. Selection of sophisticated, reasonable structure, improving processing technology. finishing strong rigidity. Stable performance.

VI. Grinding head, grinding head upper part and key bearings are used in the central automatic lubrication system.

VII. Grinding power transmission using joint belt teeth narrow V belt, greatly reducing the power loss and increase the service lift.

3. Techinical Data

Appellation

polishing width

300-1250mm or 2100mm available

polishing thickness

15-50mm or 50-100mm

belt adv speed

800-3700mm

polishing head motor

7.5kw/11kw/15kw

total motor

7.5kw/11kw/15kw ×Number of heads

weight

Depends on head qty

water consumption

15-20m³/h

size

depends

frequency converter

Schneider (Germany)/YASKAWA(JAPAN)

PLC system

Omron (Japan)

contactor

Shihlin Electric (Taiwan)

switch

SIEMENS (Germany)

Country : India Type : CNC Stone Bridge Saw Client's Background: An Indian customer opened a small stone finishing factory locally this year, focusing on the processing and pro...

Country: Saudi Arabia Type : multi-blades stone bridge saw Client's Background: The client's company is a large stone processing factory, mainly engaged in stone mining, processi...

Introduction: 5 Axis w ater Jet cutting m achine consists of four parts: a cutting platform, a CNC operating system, a high-pressure system, and an automatic water jet sand feeding syst...

Specification: Name Unit DFQ-W(5+1)450 DFQ-W(5+1)600 Blade diameter mm Φ 350~450 Φ 450~600 Maximum processing size(L*W*H) mm ...

Introduction 4+1 Axis Bridge Cutter is based on the 4axis bridge cutter machine and adds an engraving head that is suitable for drilling or cutting granite, marble, and quartz stone counte...