Price:

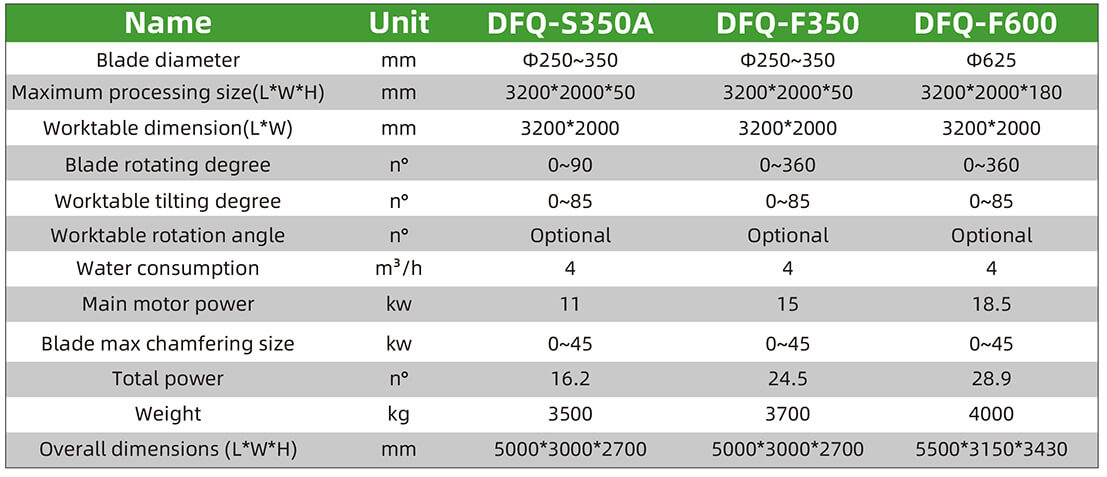

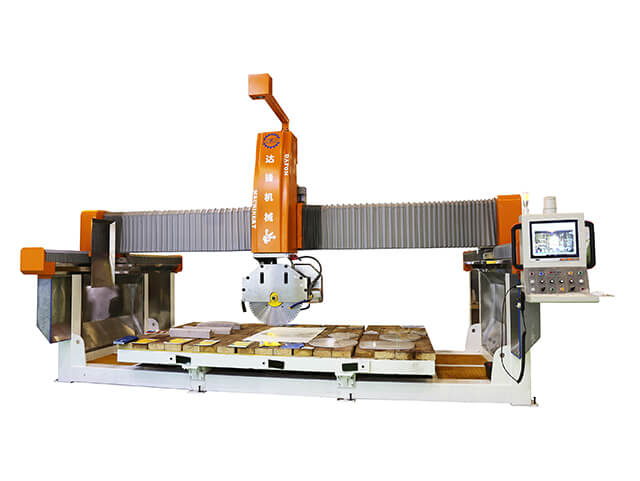

Model Number: DFQ-F350/F600

Power: 24.5/28.9KW

Application: Stone industry

Weight: 3500/4000kg

Place of Origin: CHINA.

Brand Name: DAFON

Certification: CE, ISO

Minimum Order Quantity: 1 SET

Trading Method: FOB/CIF/EXW Xiamen Port

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

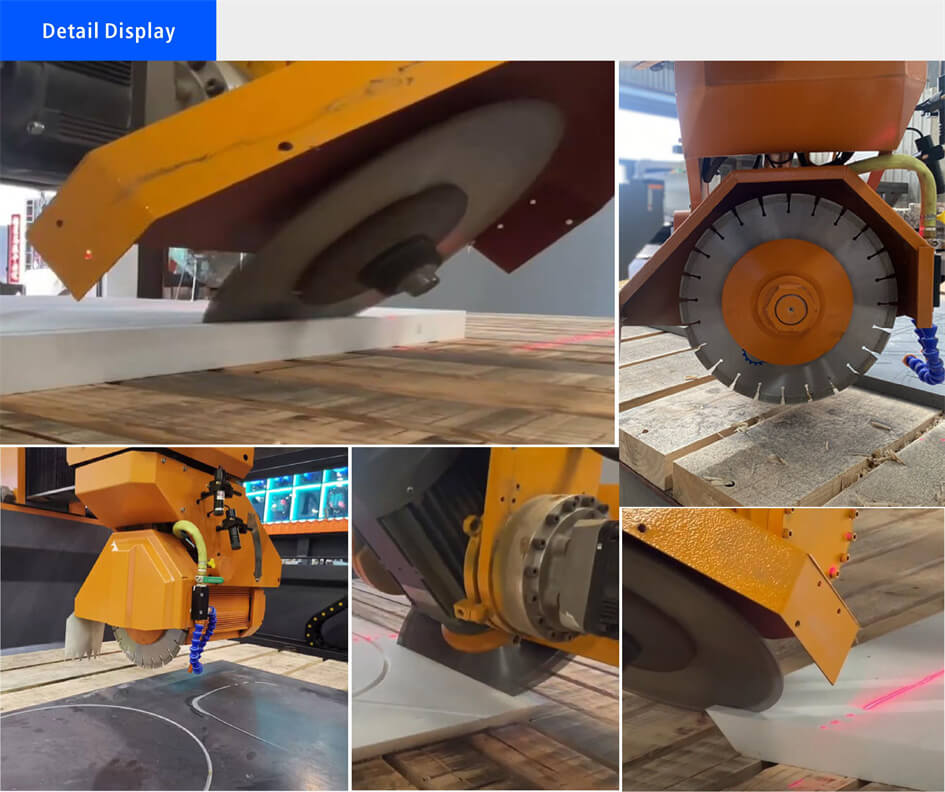

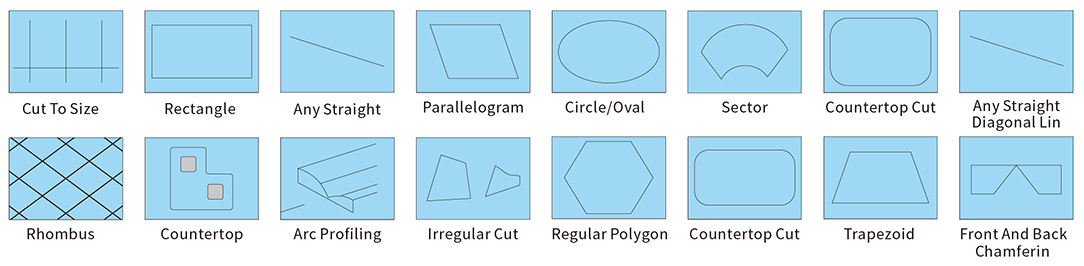

The 4-axis CNC bridge saw uses advanced CNC technology to achieve precise cutting and processing. It is equipped with a high-speed motor and precision slide rails, which can meet the stone processing needs of various specifications and make the stone craftsmanship more colorful. XYZC four-axis, C-axis automatically rotates 0~180 degrees, can cut horizontally, vertically, diamond-shaped, and 45° oblique cutting. The cutting shapes are also diverse, such as circle, arc, oval, rectangle, square, diamond, trapezoidal, fan-shaped, etc. The 4-axis cnc bridge saw is one of the most widely used mechanical equipment in the stone processing industry. It is an efficient, precise, and stable equipment that can perfectly solve various problems in stone processing.

Machine Details

Specification

Features

The 4-axis stone bridge cutting machine is an efficient, precise, multi-functional, safe, energy-saving, and environmentally friendly stone-cutting equipment that can improve the efficiency and quality of stone cutting. It is one of the important equipment in the modern stone processing industry.

The difference between 3-axis and 4-axis CNC bridge saws

3-Axis CNC bridge cutting machine: The 3-axis CNC bridge cutting machine is suitable for simple straight and curved cutting tasks. They typically only have X, Y, and Z axes, allowing horizontal, vertical, and depth-of-cut control, but no rotation of the cutting tool or work piece. Choosing a 3-axis CNC bridge saw is usually suitable for handling simpler stone cutting needs, such as straight line cutting, edge trimming, etc.

4-Axis CNC bridge saws:A 4-axis CNC bridge saws have X, Y, Z, and A axes, where the A axis is used for the rotation of the cutting tool or work piece. This enables 4-axis cutting machines to perform more complex cutting operations such as arcs, engraving, and bevel cutting. Choose a 4-axis CNC bridge saw for tasks that require higher precision and more complex cutting, such as custom engraving, pattern design, and more.

The 4-axis CNC bridge saw is a state-of-the-art machine that can cut both straight lines and curved lines. One of the most common cuts is the 45-degree bevel, often used to create a more delicate or decorative edge on countertops, stair treads, or other surfaces.

To cut a 45-degree bevel, a CNC saw uses four axes of motion: X-axis (left to right), Y-axis (front to back), Z-axis (up and down), and A-axis (rotation). The A-axis refers to the rotation of the saw blade itself. By tilting the blade at a 45-degree angle, the machine can make precise cuts along the edge of the material, removing enough material to create the desired bevel.

Living room: a high-grade atmospheric decoration style, adding natural beauty and texture to the home space. Dining room: to enhance the overall beauty o...

Give the space a stronger sense of wholeness and high-class atmosphere...

To enhance the overall beauty of the space, to create a comfortable dining environment...

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse be...

Specification: Name Unit DFQ-W(5+1)450 DFQ-W(5+1)600 Blade diameter mm Φ 350~450 Φ 450~600 Maximum processing size(L*W*H) ...

Introduction: 5 Axis w ater Jet cutting m achine consists of four parts: a cutting platform, a CNC operating system, a high-pressure system, and an automatic water jet sand fe...