Price:

Model Number: DFLSX1200-13s

Power: 22KW/55KW

Application: Stone Industry

Weight: 20T

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

The development background of curbstone machine

Kerbstones are often used in the construction of both sides of the road to protect the road surface from rainwater and are indispensable in urban construction. Therefore, the demand in urban construction is very large, but curb stones are usually obtained by purchasing prefabricated parts or making them with molds. The former has a greater economic investment and the latter is slower in efficiency. The curb stones are made of natural granite with a uniform texture. It is processed by mechanical cutting. The strength of the stone must be qualified. It is required to have uniform color, no cracks on the surface, complete edges and corners, consistent appearance, no obvious spots or color difference, no weathering is allowed, and no dropping, smashing, bumping, or bumping is allowed during loading and unloading, to avoid causing damage. The materials are cut to a uniform length, and the exposed surface must be machine-cut and polished. The allowable error of the length is within the range of ±20mm, and the allowable error of the width, thickness, and height is within the range of ±2mm.

The Features of Kerbstone cutting machine

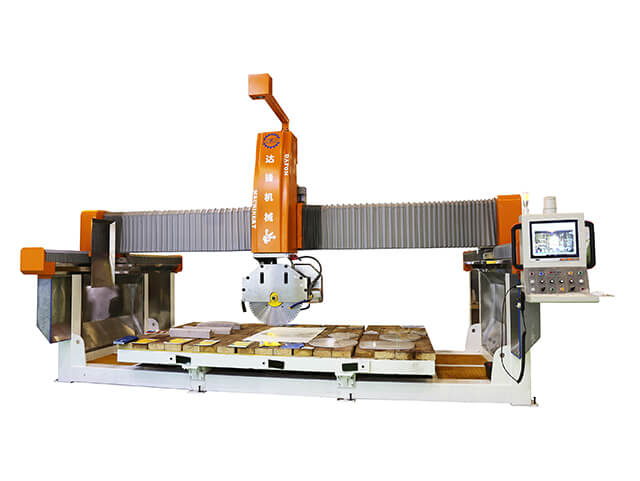

dafon machinery provides a kerbstone cutting machine line, which is a kind of stone processing equipment. It is mainly used for processing roadside stones, curb stones, monument stones, square stones, cornerstones and other types of professional equipment. It cuts the front part into pieces and the back part. The stone processing line is equipped with two integrated machines and is highly efficient.

Here we recommend a Kerb Stone Cutting Machine, which has the following advantages:

1. Automated production line, easy to operate, non-stop 24 hours a day

2. Save 50% manpower and reduce labor intensity

3. Quick disassembly and assembly, convenient transportation, and low requirements on the working site

4. No professional training required, safe and reliable, effectively reducing accidents for personnel at the construction site

|

Complete Machine Line (1 Edge Cutting Machine + 1 Slicing Machine) |

||||

|

Slicing Machine DF1200-12S |

|

Edge Cutting Machine DF1200-1S |

||

|

Dimension |

6000×3000×2800mm |

|

Dimension |

6000×4000×4500mm |

|

Diameter of blade |

1200mm |

|

Diameter of blade |

1200mm |

|

Number of blades |

12pcs |

|

Number of blades |

1pcs |

|

Max.cutting size |

3000×1800×450mm |

|

Worktable size |

2500×1800mm |

|

Worktable size |

2500×1800mm |

|

Working length max |

2500mm |

|

Weight |

10t |

|

Max.vertical stroke |

600mm |

|

Max.cutting depth |

450mm |

|

Weight |

9t |

|

Main motor power |

55kw-6 |

|

Max.cutting depth |

450mm |

|

Max.vertical stroke |

600mm |

|

Main motor power |

22kw-6 |

|

It produces about 30-35m³ of stone every day (24h) and covers a total space of 12m*5m. |

||||

Country : India Type : CNC Stone Bridge Saw Client's Background: An Indian customer opened a small stone finishing factory locally this year, focusing on the processing and pro...

Bridge stone is primarily a tire manufacturer and does not produce stone cutting machines. However, there are several companies that manufacture and sell bridge stone cutting machines. These...

The bridge saw machine adopt cast iron on the main part of machine body ensure stability while cutting The cutting speed is controlled by inverter to achieve stepless adjustment, the head mo...

Introduction: 5 Axis w ater Jet cutting m achine consists of four parts: a cutting platform, a CNC operating system, a high-pressure system, and an automatic water jet sand feeding syst...

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse belly edge, ...