Price:

Model Number: DF- 2500/2800/3200

Power: 15/18.5/22KW

Application: Machinery & Hardware, Construction, Stone

Weight: 12T

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

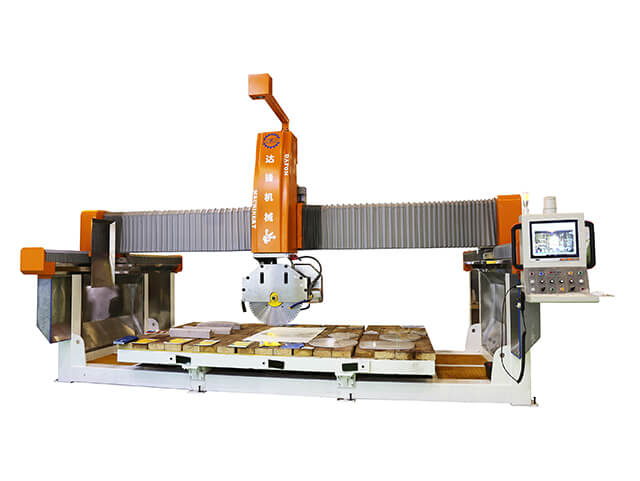

A stone gantry large cut is a stone processing tool that is typically used to process large stone blocks. It is accomplished with a machine called a gantry cutter, which has two height adjustable bridges across the processing area that are equipped with cutting heads and cutting tools.

The stone gantry large cutting technology can be used to process various types of stone, including marble, granite, sandstone, limestone, etc. The technology allows for efficient cutting and processing and can produce stone products of various shapes and sizes, such as building facade panels, floor tiles, decorative granite, etc.

1. Customer need to prepare two sides foundation first with drawing provided by us

2. Install machine and blades

3. Machine cut

4. take down the slab from block one by one, we can make a mould to support the slab, machine can cut directly to the end and slab will not fall apart

5. Trolley is optional according to customers’ requirement

|

Name |

DF-2500 |

DF-2800 |

DF-3000 |

Unit |

|

main motor power |

45 |

55 |

75 |

KW |

|

Diameter of blade |

Ø1600-2500 |

Ø1600-2800 |

Ø1600-3200 |

mm |

|

Lifting Stroke |

1250 |

1200 |

1100 |

mm |

|

slicing range |

2200 |

2200 |

220 |

mm |

|

Blade Number |

1-12 |

13-18 |

18 |

Pieces |

|

cutting stroke |

5000 |

5000 |

5000 |

mm |

|

weight |

12500 |

14000 |

15500 |

kg |

|

overall dimensions(L*W*H) |

8000*4500*6500 |

8000*4500*6500 |

8000*4500*6500 |

mm |

The general setting of blade spacing and cutting size of multi-knife gantry large cutting will vary due to different cutting needs. Generally speaking, the more blades there are, the narrower the cutting interval will be. In some finer cutting operations, higher precision and finer spacing are required, so more blades are required to cooperate to complete. In some large cutting tasks, the spacing of the blades can be relatively loose to improve efficiency.

Generally speaking, the cutting size of multi-knife gantry cutting is also set according to the task requirements to achieve the best cutting effect. Under the same cutting depth condition, the smaller the blade size, the higher the cutting economy. However, when cutting materials with higher hardness, a larger blade is required to improve the wear resistance and life of the blade in cutting.

Different cutting intervals will affect cutting efficiency and precision, narrow intervals can improve cutting accuracy and surface quality, but will reduce cutting speed; on the contrary, wide intervals can increase cutting speed, but will reduce cutting accuracy and surface quality. Therefore, in the actual multi-knife gantry large-scale cutting operation, it is necessary to set a reasonable blade spacing and cutting size in combination with specific conditions to achieve the best cutting effect.

1.The kerb stone cutting machine n ofoundation needed, easy installation, easy for shipping. 2. The kerb stone cutting machine adopts enlarged trolley, 2 p ieces of block can be cut a...

Mr. Smith, owner of a kitchen countertop manufacturing company in Poland, had been considering investing in a new CNC bridge saw for some time. After several months of research, he concluded...

The bridge saw machine adopt cast iron on the main part of machine body ensure stability while cutting The cutting speed is controlled by inverter to achieve stepless adjustment, the head mo...

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse belly edge, ...

Introduction: 5 Axis w ater Jet cutting m achine consists of four parts: a cutting platform, a CNC operating system, a high-pressure system, and an automatic water jet sand feeding syst...