Price:

Model Number: DFLSX1200-13S

Power: 22KW&55KW

Application: Machinery & Hardware, Construction, Stone

Weight: 20T

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

The Curbstone Cutter line consists of a slitting machine a edge cutting machine, a chamfering machine, and a kerbstone polishing machine. The main machine of the slitting machine adopts a four-column hydraulic locking structure, which effectively reduces the shaking during the cutting process and improves the processing accuracy. The fixed-length machine adopts beam displacement positioning.

The curb stone assembly line is divided into three parts:

cutting part

It consists of a slitting machine and an edge-cutting machine. The stone blocks are cut into stone strips or slabs of specified sizes through the slitting machine and are automatically pushed to the fixed-length machine through a transition conveyor, saving labor. Cut to length by edge cutting machine.

Rounded part

Grind the edge of the stone to 45 degrees or grind it into a bevel angle according to the angle required by the design. When it comes to curb stone chamfering machines, one chamfering and two rounding are used to improve the overall rounding speed.

polished part

This part is mainly responsible for the special curb stone polishing machine, which polishes the surface of the formed curb stone to make its surface smoother. The grinding wheel grinds away any rough or uneven planes to form a smooth and uniform surface.

Benefits

1. Segments saving: machine use multi-blade cut at the same time, every down cut is about 3-5mm(depends on stone and segment), which save segments consuming.

2. Labor saving: the entire machine line only need one worker to attend to it, machine adopts rollers to transfer stone and sensors for automatic stop and operation.

3. Workshop space saving: compared to other cutting methods, the machine need only 12*5m space when producing same capacity.

Features

1. no cement foundation needed, easy installation and shipment(40’’ HQ).

2. the main shaft adopts high frequency modulation treatment, which will be more durable and wear-resisting.

3. kerb stone cutter uses main spindle and a vice spindle to seal all saw blades together which can ensure the machine stable while cutting hard granite.

4. it uses a simple program of movement on the controlling box, easy for setting, operating, and maintaining.

5.Kerb Stone Cutting Machine adopts two hydraulic pillars(a set of hydraulic systems) on both sides of the machine to ensure the strength of cutting spindle lifting up and down.

6. Unlike traditional stone cutting, it dramatically increases productivity and reduces labor cost and power consumption and it consumes less diamond segment per cubic meter of production compared to the traditional cutting machine.

7. Cast iron is adopted in the main frame of the machine to make the machine more stable with less chance of vibration under the operating condition.

8. The regular worktable length of the shaft is 1.6m(1.8m optional)

Technical Data

|

Complete Machine Line (1 Edge Cutting Machine + 1 Slicing Machine) |

||||

|

Slicing Machine DF1200-12S |

|

Edge Cutting Machine DF1200-1S |

||

|

Dimension |

6000×3000×2800mm |

|

Dimension |

6000×4000×4500mm |

|

Diameter of blade |

1200mm |

|

Diameter of blade |

1200mm |

|

Number of blades |

12pcs |

|

Number of blades |

1pcs |

|

Max.cutting size |

3000×1800×450mm |

|

Worktable size |

2500×1800mm |

|

Worktable size |

2500×1800mm |

|

Working length max |

2500mm |

|

Weight |

10t |

|

Max.vertical stroke |

600mm |

|

Max.cutting depth |

450mm |

|

Weight |

9t |

|

Main motor power |

55kw-6 |

|

Max.cutting depth |

450mm |

|

Max.vertical stroke |

600mm |

|

Main motor power |

22kw-6 |

|

It produces about 30-35m³ of stone every day (24h) and covers a total space of 12m*5m. |

||||

Customers' Spot

Infrared CNC stone cutting machines are becoming increasingly popular due to their high precision and accuracy in cutting stone. These machines use infrared technology to locate the positio...

We recently completed a successful shipment order for our Infrared CNC Bridge Saw Machine. This machine was purchased by a stone manufacturing company from India. Here is the case of our del...

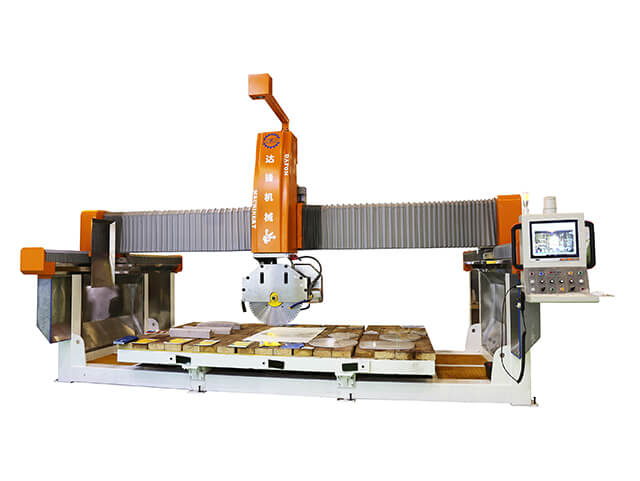

The bridge saw machine adopt cast iron on the main part of machine body ensure stability while cutting The cutting speed is controlled by inverter to achieve stepless adjustment, the head mo...

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse belly edge, ...

Introduction 4+1 Axis Bridge Cutter is based on the 4axis bridge cutter machine and adds an engraving head that is suitable for drilling or cutting granite, marble, and quartz stone counte...