Price:

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Application: Machinery & Hardware, Construction, Stone

Weight: Depends on head quantity

Brand Name: DAFON

Certification: CE, ISO

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction

Stone slab polishing machine is a kind of mechanical equipment specially used for surface polishing of large stone slabs. It uses high-speed rotating polishing disc and abrasive materials to repeatedly rub the surface of the stone slab to achieve a bright and smooth effect.

Features of stone slab polishing machine

Wide application range: It can be used for stone slabs of various sizes and thicknesses.

High efficiency: It has a high degree of automation and its production efficiency is much higher than that of manual labor.

Stable quality: The polishing effect is uniform and the quality is stable.

Easy operation: The human-machine interface is friendly and the operation is simple.

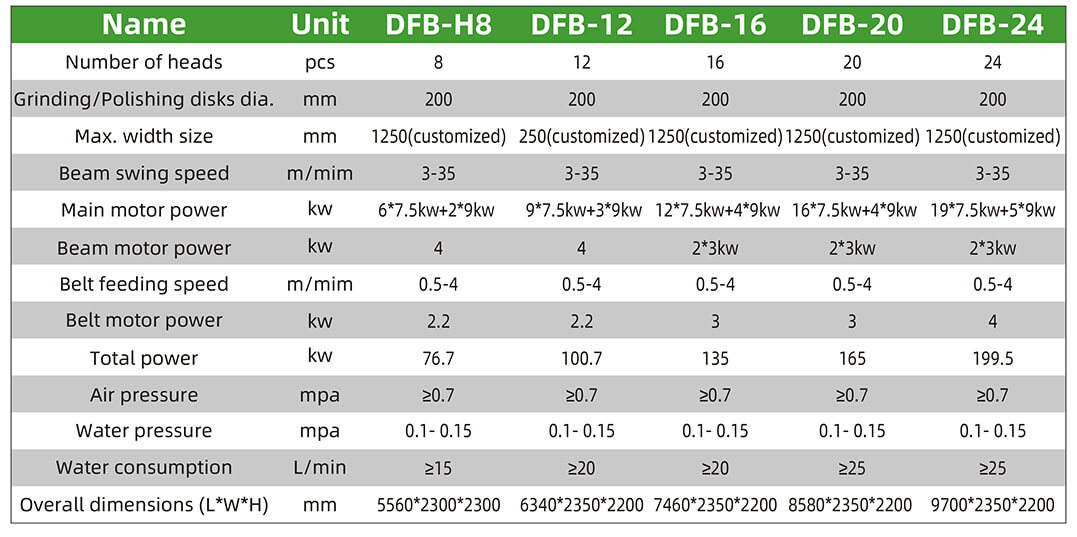

Specification

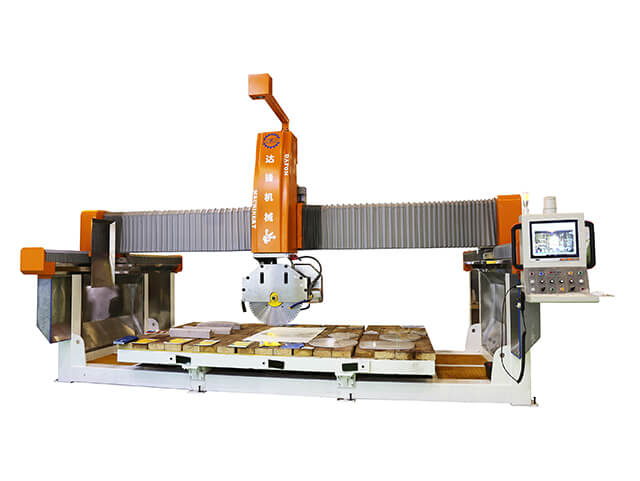

Machine Show

Finished Products

FAQ

Q: What types of stone are suitable for line polishing machine?

A: It is suitable for polishing a variety of natural and artificial stones such as marble, granite, limestone, sandstone, etc.

Q: What is the degree of automation of line polishing machine?

A: Equipped with PLC control system and human-machine interface, it has a high degree of automation. You only need to set the processing parameters to achieve automatic polishing.

Q: What is the processing efficiency of stone slab polishing machine?

A: The continuous processing mode can quickly and efficiently process large quantities of stone, greatly improving production efficiency.

Q: Is the cost of abrasives for stone slab polishing machine high?

A: The cost of abrasives is relatively low, especially the resin grinding head and grinding disc have a long life, which helps to reduce the overall production cost.

Q: Is the operation of line polishing machine difficult?

A: It adopts an advanced control system, which is very simple to operate. It only requires basic training to get started, suitable for operators with different experience levels.

Q: How to maintain line polishing machine?

A: Maintenance is relatively simple. Daily cleaning and regular inspection of the wear of the grinding head and grinding disc are required to ensure long-term and efficient operation of the equipment.

Q: What is the polishing accuracy of the slab polishing machine?

A: The use of high-precision grinding heads and grinding discs can achieve high-precision surface treatment to ensure the smoothness and flatness of the stone.

Q: What is the production adaptability of the slab polishing machine?

A: It is suitable for mass production and can also be flexibly adjusted to meet the processing needs of stones of different sizes and shapes.

Q: Will the slab polishing machine damage the surface of the stone?

A: No, the granite line polishing machine is precisely designed. By accurately controlling the polishing force and speed, it can effectively avoid damage to the surface of the stone.

Q: How to choose a granite line polishing machine that suits my needs?

A: It is necessary to consider factors such as production scale, stone type, processing accuracy requirements and budget. It is recommended to consult professional manufacturers or technicians for evaluation and recommendation.

Country: Moldova Type : kerb stone cutter processing Line Client's Background: The Moldovan customer is a company engaged in the production of building materials. It has a...

Client's Background: An Indian stone processing factory mainly engages in the processing and sales of granite, marble and other stones. The customer's outdated stone processing equipment c...

Introduction 4+1 Axis Bridge Cutter is based on the 4axis bridge cutter machine and adds an engraving head that is suitable for drilling or cutting granite, marble, and quartz stone counte...

Introduction: 5 axis CNC bridge cutter is for special shape and high accuracy slab cutting, especially for polygonal, triangular sector countertops, oval, rhombus, round, horse belly edge, ...

Specification: Name Unit DFQ-W(5+1)450 DFQ-W(5+1)600 Blade diameter mm Φ 350~450 Φ 450~600 Maximum processing size(L*W*H) mm ...