Price:

Model Number: DFQ-H450/600/800

Power: 15/18.5/22KW

Application: Machinery & Hardware, Construction, Stone

Weight: 8000/8500/8800 KG

Place of Origin: CHINA.

Brand Name: DAFON

Certification: CE, ISO

Minimum Order Quantity: 1 SET

Trading Method: FOB/CIF/EXW Xiamen Port

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

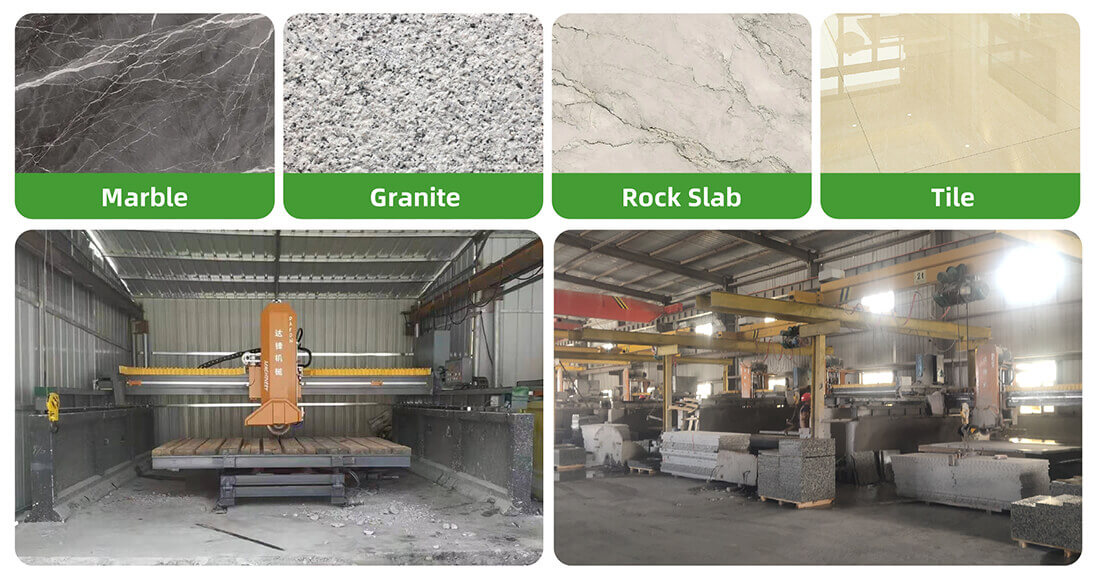

Infrared bridge stone cutting machine is a high-efficiency, high-precision, easy-to-operate, safe, and reliable stone cutting equipment. lt adopts a laser line that can quickly and accurately cut various stone materials, such as granite, marble, tiles, etc. The infrared bridge stone cutting machine can achieve perfect cutting with high accuracy and ensures the cutting quality with high efficiency. At the same time, thebridge cutting machine adopts an intelligent PLC control system, which is simple and convenient to operate. and can easily complete stone cutting work without professional skills.

There are three conventional infrared bridge stone cutting machines on the market, which are divided into three categories according to the diameter of the cutter head, the conventional DF450, DF600, and DF800. The main difference is the depth of cutting. Which one is suitable for your process, depends on the size of the stone slab processing

DFQ-H450:The maximum diameter of the saw blade that can be hung is 450mm, and the maximum depth that can be cut into stone is 110mm.

DFQ-H600:The maximum diameter of the saw blade that can be hung is 600mm, and the maximum depth that can be cut into stone is 180mm.

DFQ-H800:The maximum diameter of the saw blade that can be hung is 800mm, and the maximum depth that can be cut into stone is 280mm.

|

Name |

DFQ-H450 |

DFQ-H600 |

DFQ-H800 |

Unit |

|

Blade diameter |

Ø300~450 |

Ø350~600 |

Ø400~800 |

mm |

|

Max.vertical stroke |

230 |

350 |

350 |

mm |

|

Worktable tiling degree |

0~85 |

0~85 |

0~85 |

N° |

|

Worktable rotating degrees |

0~90/0~360 |

0~90/0~360 |

0~90/0~360 |

N° |

|

Max.cutting depth |

110 |

180 |

280 |

mm |

|

Water consumption |

1.8 |

1.8 |

1.8 |

m³/h |

|

Main motor |

15 |

18.5 |

22 |

kw |

|

Total motor |

24.5 |

26 |

26 |

kw |

|

Overall dimension (L*W*H) |

6000*4800*2900 |

6000*4800*3000 |

6000*4800*3000 |

mm |

|

Gross weight |

6560 |

7580 |

8250 |

kg |

|

Worktable dimension |

3200*2000 |

3200*2000 |

3200*2000 |

mm |

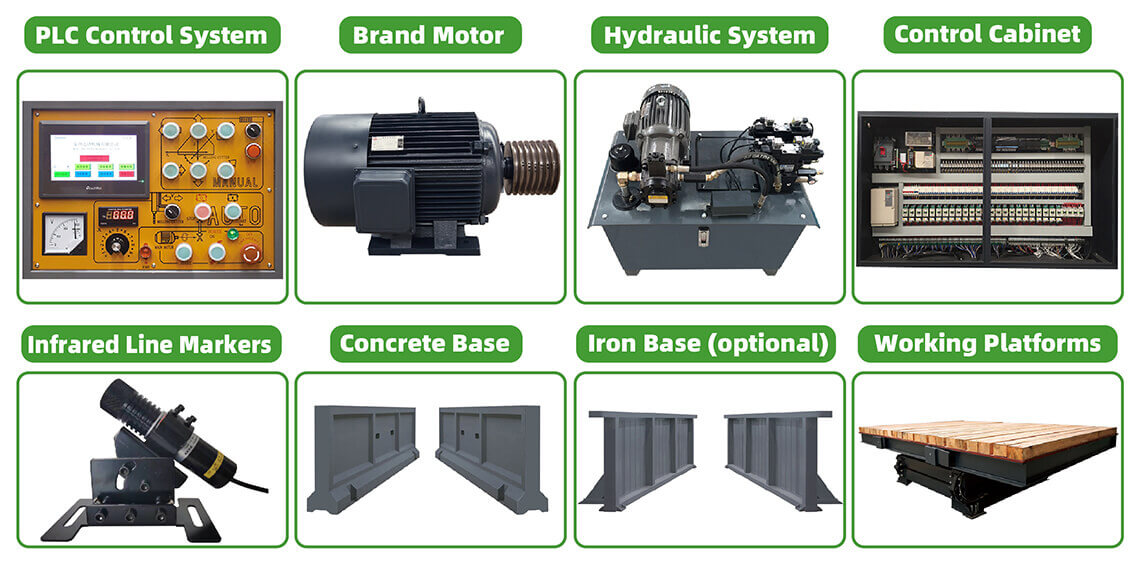

1. It is made of a casting beam to avoid distortion after long-term use and in a low-temperature environment. side beams are fixed on the steel, solid and stable.

2. The bridge-cutting machine granite speed is controlled by the inverter to achieve step-less adjustment, the head movements, table title up, rotation, and position use hydraulic transmission to move. stone cutter saw machine can be cut manually and fully automatic easily.

3. Bridge stone cutting machine adopts a PLC programmable control system and touch screen operator and is combined with high precision encode positioning(Omron brand encoder).

4. The Worktable can tilt 0-85° and can rotate 0-90°, it is convenient for cutting stone

5. The machine is easy to operate and maintain, even for operators with little experience.

Granite Countertops

The bridge cutting machine is perfect for cutting granite slabs into accurately sized pieces for creating custom countertops with smooth edges and precise dimensions.

Tile Production

This machine excels at cutting granite blocks into tiles of various sizes and thicknesses. It ensures consistent quality and precision, making it an ideal solution for tile manufacturers.

Monument/Headstone Carving

The machine's advanced technology and precise cutting abilities make it suitable for intricate carving and shaping of granite to create unique and personalized monuments and headstones.

Specification: Name Unit DFQ-W(5+1)450 DFQ-W(5+1)600 Blade diameter mm Φ 350~450 Φ 450~600 Maximum processing size(L*W*H) ...

Introduction Features Technical Data Application...

Introduction 4+1 Axis Bridge Cutter is based on the 4axis bridge cutter machine and adds an engraving head that is suitable for drilling or cutting granite, marble, and quartz st...

Experience unmatched accuracy and efficiency with our granite cutting saw, delivering flawless cuts every timeRohullah amiri 2024-08-13

The bridge saw for granite delivers unmatched accuracy and strength, turning every cut into perfectionMr. Kamlesh 2024-08-13

I've been thoroughly impressed with the precision and durability of this milling cutter. It delivers consistently clean cuts and has significantly improved the efficiency of my machining projects.Krishna Karwa 2024-06-29